- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-13 Origin: Site

Have you ever wondered how a single sheet of metal can transform into a versatile mesh structure? A 4x8 sheet of expanded metal does just that, offering strength and flexibility for diverse applications. In this post, you'll learn about its importance, various uses, and how it can meet your project needs effectively.

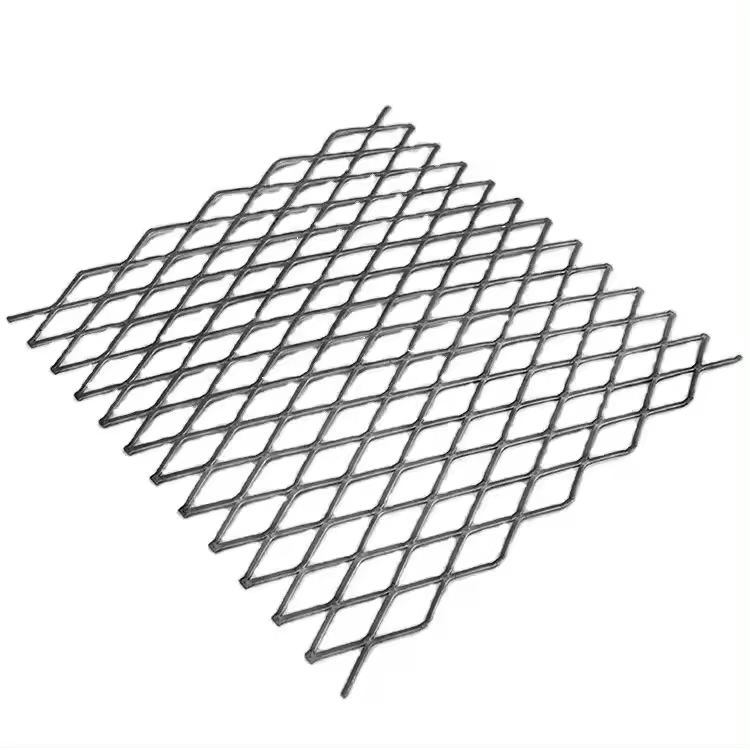

Expanded metal is a versatile material created by cutting and stretching a metal sheet to form a pattern of diamond-shaped openings. This process transforms a solid sheet into a mesh-like structure without losing any material. The metal is slit and then expanded, which increases its surface area and allows light, air, and liquids to pass through easily. This makes expanded metal both lightweight and strong, ideal for various applications.

The manufacturing process begins with a flat sheet of metal, often carbon steel, aluminum, or stainless steel. The sheet is fed into a machine that makes precise cuts and stretches the metal simultaneously. This creates a uniform pattern of openings, typically diamond-shaped, but other shapes exist depending on the mold used. After expansion, some sheets undergo flattening to produce a smooth surface, which is safer for handling and more aesthetically pleasing.

Expanded metal comes in several types based on the surface finish and pattern style:

● Standard (Raised) Expanded Metal: This type keeps the metal strands raised after expansion, providing a textured surface. It’s often used for applications requiring extra grip, like walkways or stair treads.

● Flattened Expanded Metal: After expansion, this metal is passed through rollers to flatten the raised strands, creating a smooth, flat surface. It’s safer to handle and preferred for decorative uses or where a sleek finish is needed.

● Perforated Expanded Metal: Some expanded metals combine perforations with the expanded pattern for added design or functional purposes.

Expanded metal also varies by the size of the openings, strand width, and thickness of the base metal. These factors influence strength, weight, and appearance. For example, a 4x8 sheet can have different mesh sizes and thicknesses, tailored to specific project needs.

Manufacturers offer expanded metal sheets in various materials, including:

● Carbon Steel: Strong and cost-effective, often used in industrial and security applications.

● Aluminum: Lightweight and corrosion-resistant, ideal for outdoor and architectural uses.

● Stainless Steel: Highly resistant to corrosion and chemicals, perfect for harsh environments.

Each type and material combination serves different purposes, making expanded metal a flexible choice for many industries.

When considering a 4x8 sheet of expanded metal, several key features make it a practical and popular choice across industries. These features include a smooth surface for safety, resistance to corrosion and rust, and a lightweight yet cost-effective design.

Many 4x8 expanded metal sheets undergo a flattening process after expansion. This process presses the raised strands flat, resulting in a smooth, even surface. A smooth sheet reduces the risk of cuts or injuries during handling and installation. This safety aspect is crucial, especially in applications where people frequently come into contact with the metal, such as decorative panels, furniture, or shelving. Flattened expanded metal sheets also offer a clean, sleek appearance, making them ideal for architectural and interior design uses.

Expanded metal sheets are available in various materials, each offering different levels of corrosion resistance. Aluminum and stainless steel sheets naturally resist rust and corrosion, making them perfect for outdoor or harsh environments. Carbon steel sheets often receive surface treatments such as galvanizing, powder coating, or painting to enhance their durability against moisture and chemicals. These treatments help extend the lifespan of the metal, reducing maintenance costs and preserving appearance over time.

The expanded metal manufacturing process creates a mesh-like structure that uses less metal than a solid sheet of the same size. This design significantly reduces the sheet’s weight without sacrificing strength. Lightweight sheets are easier to handle, transport, and install, which can lower labor and shipping expenses. Additionally, using less material makes expanded metal a cost-effective choice for many projects. Aluminum expanded metal sheets, in particular, offer the best balance of lightness and durability, making them popular for applications requiring mobility or minimal structural load.

● Easy Installation: Flattened expanded metal sheets can be cut, welded, and formed using standard tools, simplifying customization on-site.

● Versatility: Their combination of strength, airflow, and light transmission suits various uses, from ventilation grilles to security fencing.

● Safety in Use: The smooth surface reduces snagging hazards and improves user comfort in everyday applications.

Understanding these features helps you select the right 4x8 expanded metal sheet for your project's specific needs, balancing safety, durability, and cost.

Expanded metal sheets sized 4x8 feet are incredibly versatile. Their unique structure and properties allow them to serve many purposes across different fields. Let's explore how these sheets are used architecturally, industrially, and even in everyday homes.

Architects and designers love 4x8 expanded metal sheets for their aesthetic appeal and functionality. The diamond-shaped openings create interesting patterns that add texture and depth to buildings. They are often used as:

● Facade cladding: These sheets cover building exteriors, offering a modern look while allowing ventilation.

● Sunshades and screens: They reduce glare and heat inside buildings without blocking light.

● Interior dividers and wall panels: Flattened expanded metal sheets provide sleek, smooth surfaces that enhance room design.

● Ceiling tiles and decorative accents: They add industrial or contemporary style to interiors.

Their ability to be powder coated or anodized in various colors expands design options. Plus, the lightweight nature makes installation easier on large projects.

In industrial settings, 4x8 expanded metal sheets are valued for strength and durability. They provide safety, security, and functionality in many ways:

● Machine guards and safety barriers: Protect workers from moving parts while maintaining visibility.

● Walkways and stair treads: The textured surface offers good grip, reducing slip hazards.

● Fencing and security walls: Expanded metal is difficult to cut or climb, making it ideal for securing properties.

● Ventilation grilles and filters: Its open structure allows airflow but keeps debris out.

● Shelving and storage racks: Strong yet lightweight sheets support heavy loads efficiently.

Materials like carbon steel and stainless steel are common in these uses due to their toughness and corrosion resistance.

Expanded metal sheets are not just for big projects. Many homeowners find practical uses for 4x8 sheets around the house:

● Furniture and shelving: Lightweight sheets serve as modern shelving surfaces or cabinet inserts.

● Fireplace screens and lamp shades: They add style while protecting from sparks or diffusing light.

● Garden trellises and plant supports: The mesh supports climbing plants and allows air circulation.

● Pet enclosures and cages: Durable and secure for keeping pets safe.

● Vent covers and air filters: Easy to clean and maintain while allowing good airflow.

Their corrosion resistance, especially in aluminum or coated steel, makes them ideal for outdoor use.

When selecting a 4x8 sheet of expanded metal, understanding the types of materials used and the surface treatments available is essential. These factors directly affect the sheet's performance, durability, and suitability for different environments and applications.

Expanded metal sheets come in several common metals, each offering unique benefits:

● Carbon Steel: This is the most widely used material for expanded metal. Carbon steel sheets provide excellent strength and durability at a reasonable cost. They are ideal for industrial, security, and structural applications. However, carbon steel can rust if left untreated, so surface treatments are often necessary to enhance corrosion resistance.

● Aluminum: Aluminum expanded metal sheets are lightweight and naturally resistant to corrosion, making them perfect for outdoor or marine environments. They are easy to handle and install due to their light weight, and they maintain their appearance well over time. Aluminum is a popular choice for architectural projects and decorative uses.

● Stainless Steel: Known for its superior corrosion resistance and strength, stainless steel is used in harsh environments where exposure to chemicals or moisture is common. It is more expensive than carbon steel or aluminum but offers longevity and requires minimal maintenance. Stainless steel expanded metal is common in food processing, medical facilities, and outdoor security applications.

● Other Metals: Occasionally, expanded metal sheets are made from brass, copper, or specialty alloys for decorative or niche industrial uses. These materials add aesthetic value or specific chemical resistance but are less common for standard 4x8 sheets.

Surface treatments improve expanded metal sheets' durability, appearance, and resistance to environmental factors:

● Galvanizing: Applying a zinc coating to carbon steel sheets protects against rust and corrosion. This treatment is common for outdoor applications and industrial environments exposed to moisture.

● Powder Coating: This process applies a dry powder finish that is baked onto the metal, creating a durable, colorful, and corrosion-resistant surface. Powder coating enhances aesthetics and is often used for architectural and decorative expanded metal.

● Anodizing: Mainly applied to aluminum sheets, anodizing thickens the natural oxide layer, improving corrosion resistance and surface hardness. It also allows for coloring, making it popular in design-focused projects.

● Painting: Liquid paint coatings provide a protective and decorative finish. Paint can be applied in various colors and is suited for both indoor and outdoor expanded metal.

● Plating: Less common, plating with metals like chrome or nickel adds decorative shine and corrosion resistance for specialty applications.

Choosing the right combination of material and surface treatment depends on the intended use, environmental exposure, and budget. For example, a stainless steel sheet may not require additional coating, while carbon steel often benefits from galvanizing or powder coating to extend its life.

Ordering a 4x8 sheet of expanded metal requires careful consideration to ensure the product meets your project’s needs. Confirming specifications and choosing the right style and material are key steps in the process.

Before placing an order, verify the exact specifications of the expanded metal sheet you need. This includes:

● Sheet Size: Standard sheets measure 4 feet by 8 feet. Confirm if this size fits your project or if custom dimensions are required.

● Style: Decide between flattened or standard (raised) expanded metal. Flattened sheets have a smooth, flat surface, ideal for safety and aesthetics. Standard sheets have raised strands, offering more grip and texture.

● Mesh Size: The size of the diamond openings (measured by Short Way of Diamond (SWD) and Long Way of Diamond (LWD)) affects strength, airflow, and appearance. Choose mesh size based on function, whether for ventilation or security.

● Strand Thickness: The thickness of the metal strands influences durability and weight. Thicker strands provide more strength but add weight and cost.

● Weight: Confirm the weight per square foot or per sheet to ensure it matches handling and structural requirements.

● Quantity: Specify how many sheets you need, as bulk orders may qualify for discounts.

Providing these details upfront helps suppliers deliver the exact product you require.

Selecting the appropriate style and material depends on your application, environment, and budget:

● Material Types:

Carbon Steel: Strong and economical, suitable for industrial or security uses. Often galvanized or powder coated for corrosion resistance.

Aluminum: Lightweight and naturally resistant to rust. Ideal for outdoor, decorative, or architectural projects.

Stainless Steel: Offers excellent corrosion resistance and strength, perfect for harsh environments or where hygiene is critical.

● Style Selection:

Flattened Expanded Metal: Best for applications requiring smooth surfaces, such as interior panels, furniture, or decorative features.

Standard Expanded Metal: Preferred for outdoor walkways, security fencing, or areas needing anti-slip surfaces.

● Surface Treatments: Decide if you need galvanizing, powder coating, anodizing, or painting. These treatments improve durability and appearance.

● Custom Options: If your project demands specific patterns, thicknesses, or sizes outside standard offerings, contact suppliers for custom manufacturing.

An example to clarify ordering details:

"I need a 4x8 sheet of flattened expanded metal, 3/4 inch mesh size (#9 pattern), made from galvanized carbon steel."

This clear description helps avoid confusion and speeds up processing.

Tip: When ordering, always provide detailed specifications including style, material, mesh size, and surface treatment to ensure your 4x8 expanded metal sheet matches your project’s exact requirements.

When considering how much a 4x8 sheet of expanded metal costs, several factors come into play. Understanding these will help you make an informed purchase that fits your budget and project needs.

1. Material TypeThe base metal significantly influences price. Carbon Steel is generally the most affordable option.

a. Aluminum costs more due to its lightweight and corrosion resistance.

b. Stainless Steel is the priciest because of its durability and rust resistance.

2. Sheet Thickness and WeightThicker sheets with heavier gauge metal cost more. Weight relates to strength, so heavier sheets suit demanding applications but increase price.

3. Mesh Size and PatternSmaller openings or finer mesh require more metal per sheet, raising costs. Larger openings use less material, lowering price.

4. Surface TreatmentTreatments like galvanizing, powder coating, or anodizing add to the cost but improve longevity and appearance.

5. Style: Flattened vs. StandardFlattened expanded metal involves extra processing, which can increase price slightly compared to standard raised sheets.

6. Quantity and SupplierBulk orders often qualify for discounts. Prices vary by supplier based on location, stock, and shipping options.

Here are some example prices to give you a ballpark idea. These are approximate and can vary by region and supplier:

Style & Material | Thickness & Mesh Size | Approximate Price (4x8 Sheet) |

Carbon Steel, 1/2" mesh, #13 | Flattened | $35 - $60 |

Carbon Steel, 3/4" mesh, #9 | Standard or Flattened | $50 - $60 |

Aluminum, 1/2" mesh, #18 | Flattened | $50 - $80 |

Aluminum, 3/4" mesh, #13 | Standard | $45 - $75 |

Stainless Steel, 1/2" mesh | Flattened | $90 - $150 |

Stainless Steel, 3/4" mesh | Standard | $100 - $170 |

Prices fluctuate depending on market conditions and supplier inventory.

● Specify all details clearly to avoid ordering mistakes.

● Compare quotes from multiple suppliers.

● Consider total cost, including shipping and handling.

● Ask about bulk discounts if ordering multiple sheets.

● Balance price against quality and durability needs.

Expanded metal sheets, especially the 4x8 size, offer versatile applications across architectural, industrial, and household uses. Key factors affecting their cost include material type, thickness, mesh size, and surface treatment. Choosing the right expanded metal sheet involves balancing price with durability and specific project needs. Shengteng International Trading provides high-quality expanded metal sheets, ensuring value through robust materials and customizable options, catering to diverse requirements.

A: A 4x8 sheet expanded metal is a metal sheet cut and stretched to form a mesh-like structure with diamond-shaped openings, commonly used for its strength and versatility.

A: The cost varies based on material, thickness, and style, ranging from $35 for carbon steel to $170 for stainless steel.

A: Expanded metal sheets are lightweight, cost-effective, and allow airflow while maintaining strength, unlike solid metal sheets.