- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-09 Origin: Site

You often find expanded metal sheets in standard sizes like 4' x 8', 48" x 96", and 60" x 120". The mesh openings can vary, with a common example being a .83" short way opening and a 2.375" long way opening at a .135 thickness.

Standard Size | Thickness | Short Way Opening (SWO) | Long Way Opening (LWO) |

|---|---|---|---|

4' x 8' | .135 | .83" | 2.375" |

Understanding these sizes helps you choose the right material for your project. You might use expanded metal for fencing, ventilation, or as a strong base for plaster. Many types and custom sizes are also available to fit your needs.

Expanded metal sheets are sold in sizes like 4' x 8' and 6' x 10'. Knowing these sizes helps you pick the right material for your job.

Mesh openings come in different sizes. The shapes are often diamond, square, or hexagonal. Use an expanded metal size chart to find what works best for you.

Thickness changes how strong the metal is. Thicker metal can hold more weight. Pick the thickness that matches what your project needs, like walkways or fences.

It is important to know terms like SWD (Short Way of Diamond) and LWD (Long Way of Diamond). These help you choose the right mesh for things like airflow and filtering.

Always look at product labels for details like size, mesh opening, and thickness. This helps you get the right expanded metal for your project.

You can find expanded metal in a range of standard sheet sizes. These sizes help you plan for projects like fencing, walkways, or screens. In the United States, common sheet sizes include 48" x 48", 48" x 96", 72" x 120", 4' x 8', and 6' x 10'. Internationally, you may see similar dimensions. These sheets fit most construction and industrial needs.

Standard Sheet Size | Metric Equivalent (approx.) |

|---|---|

48" x 48" | 1220mm x 1220mm |

48" x 96" | 1220mm x 2440mm |

72" x 120" | 1830mm x 3050mm |

4' x 8' | 1220mm x 2440mm |

6' x 10' | 1830mm x 3050mm |

You can also order custom sizes if your project requires a unique fit. Many suppliers will cut expanded metal mesh to your specifications.

Expanded metal mesh comes in many opening sizes. The most common shape is a diamond, but you may also see square or hexagonal patterns. Mesh size refers to the width and length of each opening. You measure these as the short way of the diamond (SWD) and the long way of the diamond (LWD). Standard expanded metal mesh openings range from as small as 1/4 inch up to 1-1/2 inches. Some specialty products offer even smaller or larger openings.

Plate Thickness Range | Opening Size Range |

|---|---|

0.5mm to 6mm | 3mm x 6mm to 56mm x 150mm |

You can use an expanded metal size chart to compare different mesh options. This helps you select the right mesh for your application, whether you need fine filtration or heavy-duty support.

The thickness of expanded metal affects its strength and use. You will see thickness listed in gauges or millimeters. Common thicknesses include #9, #10, and #16 gauge. Thicker metal supports more weight and lasts longer in tough environments.

Application Type | Recommended Thickness | Reason for Thickness |

|---|---|---|

Walkways and Platforms | 3mm to 6mm | Supports heavy foot traffic and provides slip resistance. |

Building Facades | 1.5mm to 3mm | Lightweight but strong enough for wind and weather. |

Filters and Screens | 0.8mm to 2mm | Thin for filtration but keeps its shape. |

Fencing and Enclosures | 2mm to 4mm | Secure and durable without being too heavy. |

Tip: Thicker expanded metal mesh works best for walkways and platforms. Thinner mesh fits well in screens and filters.

You will notice that the material type also affects available sizes. Aluminum, carbon steel, galvanized steel, and stainless steel each offer different size ranges. For example, aluminum expanded metal can be folded for decorative uses, while stainless steel comes in specific sizes for high-strength needs.

Expanded metal mesh sizes and thicknesses follow industry standards. ASTM F1267 Type II sets the guidelines for standard expanded metal. Tolerances allow for about 10% variation in weight and dimensions, but minimum thickness must meet the listed value.

If you need more details, you can always check an expanded metal size chart. This chart shows weights, design sizes, opening sizes, strand sizes, and overall thickness for different products.

Weight (pounds/100 sq. ft) | Design sizes | Opening sizes | Strand sizes | Overall thickness |

|---|---|---|---|---|

50 | .200 in | .50 in | .166 in | .024 in |

62 | .200 in | .50 in | .166 in | .030 in |

75 | .200 in | .50 in | .166 in | .036 in |

86 | .255 in | 1 in | .172 in | .036 in |

114 | .255 in | 1 in | .172 in | .048 in |

43 | .500 in | 1.20 in | .438 in | .036 in |

70 | .500 in | 1.20 in | .438 in | .048 in |

86 | 0.500 in | 1.20 in | 0.375 in | 0.060 in |

147 | 0.500 in | 1.20 in | 0.313 in | 0.092 in |

54 | 0.923 in | 2 in | 0.813 in | 0.060 in |

80 | 0.923 in | 2 in | 0.750 in | 0.092 in |

Note: Expanded metal mesh sizes and thicknesses may vary slightly due to manufacturing tolerances. Always check with your supplier for exact measurements.

Understanding expanded metal sizing terms helps you choose the right product for your project. Each term describes a different part of the mesh and affects how the material performs.

You will see SWD (Short Way of Diamond) and LWD (Long Way of Diamond) on most expanded metal sizing charts. These terms describe the shape and size of the mesh openings.

Term | Definition |

|---|---|

SWD | The length of the short diamond diagonal from one pitch point center to another pitch point center. |

LWD | The length of the long diamond diagonal from one pitch point center to another pitch point center. |

SWD measures the shorter distance between bond centers. This is important for layout and spacing.

LWD measures the longer distance between bond centers. This shapes the overall configuration of the expanded metal.

Tip: SWD and LWD affect the strength, airflow, and filtration ability of the mesh. For example, a larger LWD allows more light or air to pass through, while a smaller SWD can block smaller particles.

Gauge tells you the thickness of the base metal before it is expanded. A lower gauge number means a thicker sheet. When you look at expanded metal sizing, always check the gauge to make sure the sheet can handle the load you need.

Gauge affects the weight and strength of the expanded metal.

Thicker gauge works best for heavy-duty uses like walkways.

Thinner gauge fits well in screens or filters.

Strand width is the size of the solid metal strips that form the mesh. Wider strands make the sheet stronger and more durable. Narrower strands create a lighter, more flexible mesh, which is good for decorative or architectural uses.

Note: If you need expanded metal for a high-traffic area, choose a product with a wider strand width for better support.

Knowing these expanded metal sizing terms helps you avoid mistakes when ordering. You can match the right mesh to your project and prevent delays.

Knowing how to read expanded metal sizes helps you pick the right material. You need to understand what the labels mean. You also need to know how to measure expanded metal. This section will show you both steps.

Expanded metal products have labels with key details. These labels help you find the right sheet for your project. Always look at the label before you buy or use expanded metal.

Here is what you usually see on product labels:

Information Type | Description |

|---|---|

Brand logos and product names | Shows who made the product. |

Serial numbers and barcodes | Used for tracking and inventory. |

Safety warnings and instructions | Tells you how to use the product safely. |

Regulatory compliance information | Shows if the product meets rules and standards. |

Brand logos and product names tell you the maker.

Serial numbers and barcodes help with tracking.

Safety warnings and instructions keep you safe.

Regulatory compliance information shows if it follows laws.

Tip: Always check the label for sheet size, mesh opening, and thickness. This helps you read expanded metal sizes the right way and avoid mistakes.

You need to measure expanded metal to make sure it fits. Use a ruler or caliper for this job. Measure the mesh openings and the sheet size before you install it.

Follow these steps to measure expanded metal:

Put the sheet on a flat surface.

Use a ruler to check the length and width.

Measure the mesh openings:

Longway Pitch (LWP): Measure side to side from knuckle to knuckle or center to center.

Shortway Pitch (SWP): Measure up and down from knuckle to knuckle or center to center.

Strand Width (SWDT): Measure how wide the metal strand is.

Strand Thickness (STK): Measure how thick the raw material is.

Measurement Type | Description |

|---|---|

Longway Pitch (LWP) | Measured side to side from knuckle to knuckle or center to center. |

Shortway Pitch (SWP) | Measured up and down from knuckle to knuckle or center to center. |

Strand Width (SWDT) | Shows how wide the metal strand is. |

Strand Thickness (STK) | Shows how thick the raw material is. It does not change when expanded. |

Note: Raised mesh is good for walkways and fences because it gives grip. Flattened mesh works better for smooth surfaces like machine guards.

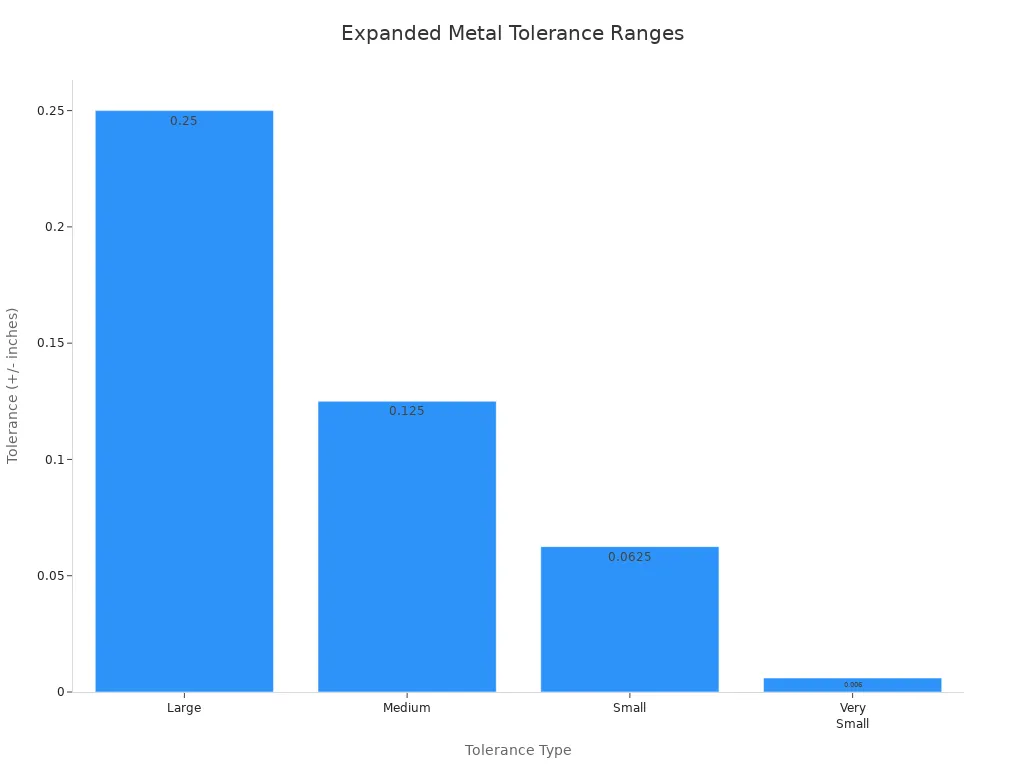

Professionals also check tolerances to make sure the size is right. Tolerances show how much the size can change. You can see examples in the chart below.

When you read expanded metal sizes and measure them, you make sure the material fits your project. You avoid problems and get the best results.

You can pick from a few types of expanded metal. Each type has its own features and size choices. Knowing the differences helps you pick the right one.

Type | Size Options | Applications |

|---|---|---|

Standard (Raised) | Many sizes and weights | Warehouse enclosures, safety guards, lockers |

Flattened | Many sizes available | Fencing, cages, flooring, ventilation systems |

Micro | Custom shapes and sizes | Filters and other special uses |

Standard raised expanded metal has a bumpy surface. The mesh sticks up to give more grip. People use it for safety guards and enclosures. It is also good for lockers. This type comes in lots of sizes and weights. Raised expanded metal grating is great for walkways because it stops slipping. You can get it in carbon steel or stainless steel. Raised expanded metal is strong and lasts a long time. It is a good choice for tough jobs.

Flat expanded metal is also called flattened expanded metal. It has a smooth surface. Makers use rollers to make it flat. This makes it thinner and easier to use. Flat expanded metal is used for fencing and cages. It is also good for ventilation systems. You can use it for floors and machine guards too. Flat expanded metal comes in many sizes. You can match it to your project. Stainless steel flat expanded metal does not rust easily. Flat expanded metal grating is lighter than raised grating. It still has good strength.

Micro expanded metal has tiny openings. You usually order it in special shapes and sizes. It works best for filters and special jobs. Micro expanded metal is not as common as the other types. But it is important for some industries.

Tip: Always check the design size before you choose expanded metal. Common design sizes are 3/4" x #10 and 1-1/2" x #16. These sizes show the opening and thickness.

Design Size | Thickness | Weight | Opening Size |

|---|---|---|---|

3/4"-#10 | .083 | 117 | .923 |

1-1/2"-#16 | .053 | 40 | 1.33 |

You can get raised or flat expanded metal in these sizes. Both types use these measurements for grating. When you pick a type, think about the surface, strength, and opening size you need.

When you pick expanded metal, think about a few things. The right size helps your project work well and stay safe. First, look at what your project needs.

Factor | Description |

|---|---|

Weight of Held Parts | Heavy loads need thicker strands and smaller openings. |

Type of Metal Used | Some metals, like stainless steel, can be thin but strong. |

Needs of the Wash Process | If you want more air or water flow, choose mesh with bigger openings and thinner strands. |

Try not to make mistakes when choosing expanded metal. Here are some things to remember:

Pick a strong material that does not rust easily.

Choose a mesh size that fits your security or airflow needs.

Make sure the thickness is enough for the weight.

Think about how the surface looks and protects.

Match the mesh type to what you need.

Check the area to stop damage early.

Follow building codes to keep things safe.

Balance your budget with how well it works.

Tip: Always check if your expanded metal follows rules like ASTM F-1267-18. This keeps your project safe and legal.

Expanded metal is used in many places every day. The size you pick changes how well it works.

Platforms use expanded metal for light support. Thicker mesh is stronger.

Machine guards keep workers safe. Small openings protect hands but let you see.

Drainage and ventilation need big openings for more airflow.

Screens and fences use different sizes for safety and letting light through.

Walkways need raised mesh for grip and safety.

Gabion walls and barriers use expanded metal for strength and bending.

Equipment covers use mesh that lets air in but blocks dirt.

Decorative projects use special patterns and sizes.

Expanded metal is strong, flexible, and lets air pass through. You can choose from many sizes for your needs. When you pick the right size, your project works better and lasts longer.

You now know the main things that describe expanded metal. These include strand size, overall thickness, SWD and LWD, percent open area, tolerance, and nominal weight per cubic foot.

Specification Type | Description |

|---|---|

Strand Size | How thick the strands are in the expanded metal. |

Overall Thickness | The total thickness of the expanded metal sheet. |

SWD / LWD | Short Way and Long Way size of the diamond per foot. |

Percent Open Area | How much of the sheet is open space instead of metal. |

Tolerance | How much the size can change from the listed number. |

Nominal Weight per CSF | The weight of the expanded metal for each cubic foot. |

You can use this information to plan your projects better. If you need a special size, talk to your supplier. They can help you get the right measurements and avoid mistakes that cost money.

Standard expanded metal has a raised, textured surface. Flattened expanded metal goes through a rolling process that makes it smooth and flat. You choose the type based on your project’s needs for grip or appearance.

You can use tin snips for thin sheets. For thicker sheets, use a power tool like an angle grinder. Always wear gloves and safety glasses to protect yourself from sharp edges.

Yes, you can paint or coat expanded metal. Clean the surface first. Use a primer for better results. Paint or powder coating helps prevent rust and improves appearance.

Measure from the center of one strand to the center of the next. Check both the short way and long way of the diamond. Use a ruler or caliper for accuracy.

You see expanded metal in walkways, fences, machine guards, and screens. It works well for both industrial and decorative projects because it is strong and allows air or light to pass through.