- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

You use Expanded Metal Sheets when you want strong, open surfaces. Makers make these sheets by cutting and pulling solid metal. This makes diamond-shaped holes. This shape lets air, light, and water go through. You often see Expanded Metal Sheets made from stainless steel, aluminum, or carbon steel. Each material has its own special benefits, as shown below:

Material | Description |

|---|---|

Stainless Steel | A rust-resistant metal mix used a lot. |

Aluminum | Light and does not rust easily. |

Carbon Steel | Strong and tough, used in building things. |

Various Alloys | Has different metal mixes for more strength. |

Expanded Metal Sheets are both strong and light. They have holes shaped like diamonds. Air, light, and water can go through these holes.

You can pick from many materials. Some choices are stainless steel, aluminum, and carbon steel. Each material has its own good points. They work for different jobs.

These sheets can be used in many ways. They are good for building things. They help in factories and for decoration. You can use them for walkways, safety guards, and furniture.

Safety is very important. The mesh design helps stop slips and falls. This makes them great for walkways and ramps.

Picking the right type and finish matters. Think about what your project needs. This helps make sure the sheet is strong, safe, and looks nice.

You can think of Expanded Metal Sheets as metal panels with a pattern of diamond-shaped openings. Manufacturers create these sheets by cutting and stretching solid metal. This process forms a mesh that is both strong and lightweight. The openings allow air, light, and water to pass through easily. You will find two main types of expanded metal sheets in the industry:

Type of Expanded Metal Sheet | Description | Applications |

|---|---|---|

Raised Expanded Metal Sheet | Has alternating ridges from overlapping metal strips, creating a diamond pattern. This design helps with air flow. | Used in lockers, warehouse fencing, and machinery safety doors. |

Flattened Expanded Metal Sheet | Cold rolled for a flat, smooth surface. It is about 5% lighter than the raised type. | Used for walkways, stairways, fencing, décor, and ventilation. |

Tip: The diamond pattern is not just for looks. It gives the sheet extra strength and helps prevent slipping.

You might wonder how Expanded Metal Sheets are made. The process uses both machines and skilled workers to turn solid metal into a mesh. Here are the main steps:

Material Selection: You choose the right metal for your needs.

Cutting: The metal sheet is cut into the size you want.

Expansion: Machines stretch the metal, making the diamond-shaped openings.

Edge Fixing: Workers reinforce the edges to make the sheet stronger.

Finishing: The sheet gets a coating or finish to protect it from rust and wear.

Quality control is important during each step. You will see checks for the size of the holes, the width of the strands, and the strength of the sheet. Standards like ASTM A478/A478M and EN 10244-2 help make sure each sheet meets industry rules.

Tolerance Type | Description |

|---|---|

Length Tolerance | Controlled within 1 or 2 pattern repeats, with a height tolerance of +50 / -0 or +25 / -0 mm. |

Width Tolerance | Usually +30 / -0 mm, based on the original sheet width. |

Out of Square Tolerance | Maximum of 5mm per meter of length or 10mm per square meter on diagonals. |

Camber Tolerance | Controlled during production to keep the sheet straight. |

Raw material testing checks the metal’s strength and chemical makeup.

In-process inspection measures the mesh size and strand width.

Final inspection checks the finished sheet for size, surface quality, and strength.

You can pick from several metals when choosing Expanded Metal Sheets. Each metal has its own strengths and best uses.

Material | Mechanical Properties | Chemical Properties |

|---|---|---|

Stainless Steel | Strong, lightweight, and resists rust. | Contains 18% chromium and 8% nickel. |

Aluminum | Very light and resists corrosion. | Alloy makeup can change based on the type. |

Carbon Steel | Very strong but less resistant to rust. | Properties depend on the amount of carbon. |

304 stainless steel can last 500 hours in salt spray without rusting.

316L stainless steel is even better against salt and chemicals, about 30% more than 304.

Aluminum is easy to handle and does not rust, so you often see it in outdoor projects.

Carbon steel is tough and works well for heavy-duty jobs, but you may need to coat it to stop rust.

Note: The right material depends on where you will use the sheet and what you need it to do.

Expanded Metal Sheets are useful in many ways. The diamond mesh lets air, light, water, and sound pass through. You can use these sheets when you need strength, safety, or a nice look.

Expanded Metal Sheets are used in lots of building jobs. Builders pick them for walkways and stairs because the mesh helps people not slip. These sheets are also used for safety guards and fences. Gates often use them too. Architects put them on buildings to block sunlight and make them look cool. The mesh is good for letting air in and keeping bugs out. It works for platforms, ramps, and even in transport projects.

Some ways to use them in construction:

Walkways & Catwalks

Safety & Machine Guards

Security Fencing & Gates

Architectural Facades & Sunshades

Industrial Flooring & Platforms

Stair Treads & Ramps

Ventilation & Screening

Filtration & Separation

Decorative Panels & Interior Design

Infrastructure & Transportation

Expanded Metal Sheets are light but very strong. They do not rust easily and do not need much care. You save money because they are simple to move and put in place.

Benefit | Description |

|---|---|

Lightweight yet strong | Aluminium expanded metal is light but still strong, so it does not weigh down buildings. |

Excellent corrosion resistance | The natural coating stops rust and damage, so the sheets last longer. |

Expanded Metal Sheets are found in many factories. Workers use them for walkways and safety platforms. Machines are kept safe with these sheets as guards. Food plants use them for vents and covers. Chemical and drug companies use them to cover equipment. Power plants and dams use them for support and safety. Marine jobs use them for docks and ramps. Public places use them for bridges and drain covers. Transit systems use them for floors and stairs.

Industrial Sector | Purpose |

|---|---|

Industrial Structures | Used for lifts and strong support. |

Food Industry | Used for safety and letting air move. |

Chemical and Pharmaceutical Industry | Used to cover equipment and keep things safe. |

Cement Plants | Used for support and safety. |

Dams | Used for safety and to keep things strong. |

Power Plants | Used for work platforms and barriers. |

Ship and Yacht Construction | Used for building and fixing boats. |

Social Facilities | Used for looks and safety. |

Marine and Coastal Projects | Used for docks and ramps for boats. |

Public Infrastructure | Used for bridges and drain covers. |

Transportation and Transit Systems | Used for floors and stairs. |

Energy and Utility Projects | Used for vent covers and work platforms. |

Agriculture and Food Processing | Used for safety and walkways. |

Expanded Metal Sheets can make spaces look special. Designers use them for building fronts and sun blockers. These sheets are good for fences, railings, and ceiling panels. You see them in walls that let light and air through. Artists use them in art pieces. Furniture makers use them for chairs, tables, and store displays to look modern.

Some popular decorative uses:

Decorative divider walls

Wall and ceiling panels

Furniture and fixtures

Staircases and railings

Lighting fixtures

Facades and screens

The mesh pattern gives rooms a cool look and feel. You can paint or coat the sheets to fit your style.

Expanded Metal Sheets help keep people safe in many places. The strong mesh helps people not slip on walkways and ramps. It makes tough fences and machine guards. These sheets do not rust and last a long time outside. Security fences made from expanded metal are hard to break. You see these sheets where safety and strength are needed.

Feature | Description |

|---|---|

Sturdy Structure | The diamond mesh is strong and stops slipping. |

Durable & Weatherproof | The metal and coatings help the sheets last in bad weather. |

Effective Barrier | The mesh makes a strong fence or guard that is hard to get through. |

Expanded Metal Sheets are strong, last a long time, and can be used in many ways. You can use them in buildings, factories, and for safety.

You get strong support when you use Expanded Metal Sheets. The diamond-shaped openings help balance airflow and strength. For example, the 3 4 13 expanded metal specification is popular in factories because it works well under pressure. You can choose sheets with different thicknesses, from 0.8mm to 12.7mm. Thicker sheets can handle up to 890 PSI, which means they hold heavy loads. Raised expanded metal sheets give you 23% more impact resistance than perforated metal. This makes them a smart choice for walkways, safety guards, and platforms.

The open area ratio of 0.67:1 helps keep the sheet strong while letting air and light pass through.

You can rely on these sheets for both indoor and outdoor projects.

You can use Expanded Metal Sheets in many ways. Builders use them for walkways, fences, and building fronts. Factories use them for machine guards and safety screens. You see them in filters and air systems because they let air move easily. Car makers use them for flooring and grilles. Artists and designers like them for creative projects and room dividers.

You can order different mesh sizes and shapes for your needs.

The diamond pattern lets light and air move through, making spaces brighter and cooler.

These sheets work well inside and outside because they resist rust and damage.

You can pick finishes and colors to match your style.

You save money when you choose Expanded Metal Sheets. The way these sheets are made creates little waste. You do not pay for scrap metal. Perforated metal costs more, especially if you want fancy designs.

Material Type | Cost Saving Aspect |

|---|---|

Expanded Metal | Minimal waste in manufacturing, no scrap produced. |

Perforated Metal | Generally pricier, especially with complex designs. |

Steel sheets cost less than aluminum or stainless steel. Thicker sheets cost more but last longer. Finer mesh looks nice but can raise the price. If you need a coating for outdoor use, that adds to the cost.

You get better safety with Expanded Metal Sheets. The strong mesh stops slips and falls on walkways and ramps. You can use them for fences and guards that are hard to break. These sheets last a long time outside and do not rust easily. You keep people safe in factories, buildings, and public spaces.

The non-slip surface helps prevent accidents.

The sturdy design protects machines and people.

You can trust these sheets for security and safety barriers.

Tip: Choose the right thickness and finish for your project to get the best safety and durability.

Standard expanded metal sheets are used in many projects. These sheets have diamond-shaped holes and a bumpy surface. You can pick from aluminum, carbon steel, galvanized steel, or stainless steel. There are many sizes and thicknesses to choose from. Makers cut and stretch the metal to make these sheets. This makes the sheet strong and stiff. The bonds and strands line up at the same angle. This helps the sheet stay strong and not bend.

Main features:

Diamond-shaped mesh

Bumpy texture for better grip

Many material choices

Lots of sizes and thicknesses

Strong and stiff build

Flattened expanded metal sheets start as standard sheets. They become flat and smooth after going through cold rolling.

Flattened expanded metal is made by a process called "cold rolling." The sheet goes through rollers that press it flat. This removes the bumps and makes the surface even. The pattern gets stretched out, so the sheet is thinner and wider.

You can use flattened sheets for walkways, ramps, and places needing a smooth surface. These sheets are lighter and easier to move than standard ones.

Decorative expanded metal sheets help you make cool designs. You can pick from many patterns to fit your style. The diamond pattern is the most common. You can also find square, hexagonal, and round holes. Some sheets have fancy patterns for special looks. You can even get custom patterns for your own project.

Popular pattern choices:

Diamond

Square

Hexagonal

Round

Fancy

Custom designs

Decorative sheets are good for building fronts, screens, and furniture. You can paint or coat them to match your room.

Heavy-duty expanded metal sheets are extra strong. People use them for factory floors, security fences, and machine guards. The strands are thick, and the holes are small. This helps the sheet hold heavy things and take hard hits. Heavy-duty sheets work well for tough jobs in factories and building sites.

Tip: You can pick diamond, staggered, or straight patterns for any type. Each pattern gives a different look and strength.

Expanded Metal Sheets come in many types. You can choose the best one by looking at the pattern, thickness, and material.

Picking the right Expanded Metal Sheets helps your project work well. You should think about how you will use the sheets. You also need to pick the best material, size, pattern, and finish. Each choice changes how strong, safe, and long-lasting your sheet is.

First, think about what you want the sheet to do. You might need a sheet for a walkway, fence, or wall. Each job needs different things. Walkways need strong sheets that stop slipping. Walls need sheets with nice patterns and colors. Always check if the sheet follows safety rules for your project.

Here is a table that shows what to think about:

Factor | Description |

|---|---|

Material Type | Pick based on how much weight and weather it faces. |

Mesh Size and Pattern | Decide how much you want to see through and how air moves. |

Thickness and Strand Width | These change how strong and bendy the sheet is. |

Finish | Choose for inside or outside use and how it looks. |

Compliance | Make sure the sheet meets safety and building rules. |

Tip: Always check if your sheet follows local building and safety codes.

You need to pick a material that fits your project. Some materials last longer and need less care. Others cost less but may need extra help to stop rust. Here are some common choices:

Aluminum is light and does not rust. It works well outside and where weight matters.

Stainless steel is strong and does not rust. It is good for tough places like factories or near water.

Galvanized steel has a zinc layer that stops rust. It is good in wet places.

Carbon steel is very strong and costs less. You must coat it to stop rust.

Here is a table that shows how each material works:

Material Type | Durability Characteristics | Maintenance Requirements |

|---|---|---|

Aluminum Expanded Metal 5005 | Light, does not rust, great for outside use | Needs little care because it does not rust |

Stainless Expanded Metal T-304 | Very strong, does not rust | Needs little care, stays clean |

Galvanized Expanded Metal | Cheaper, zinc-coated to stop rust | Needs less care in wet places |

Carbon Steel | Very strong, costs less, but can rust | Needs a coating to stop rust |

Note: Pick a material that fits your budget and where you will use the sheet.

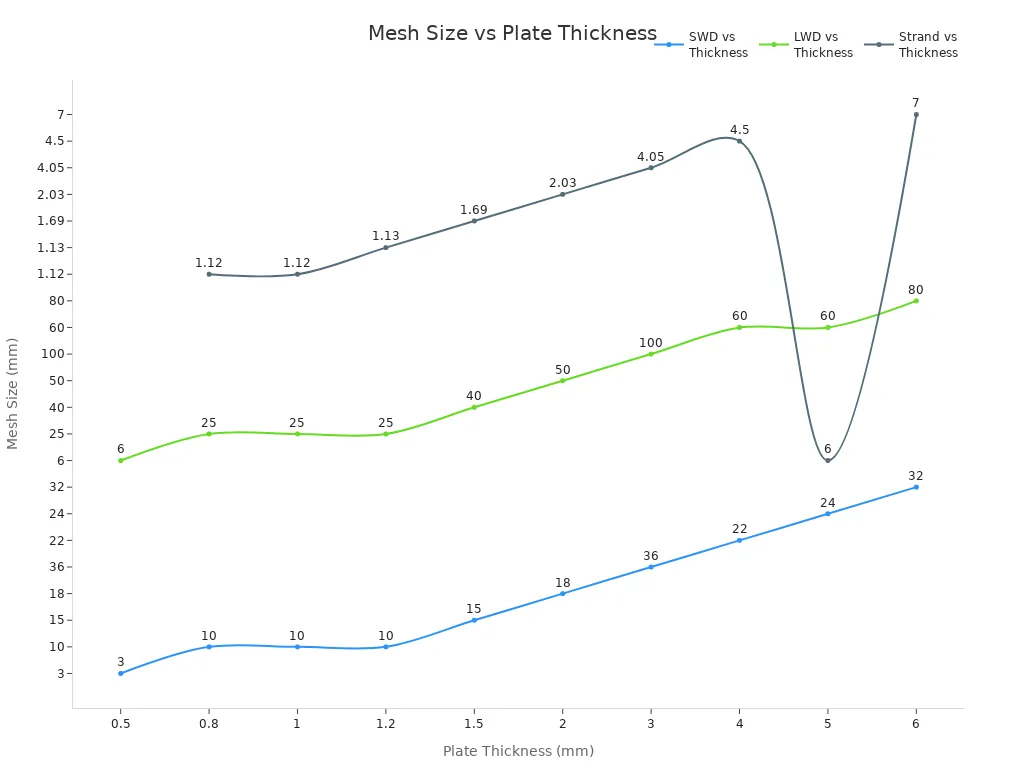

The mesh size and pattern change how the sheet works. You need to pick the right thickness, strand width, and mesh opening. Small mesh is stronger and harder to see through. Big mesh lets more air and light pass. Patterns can be diamond, square, or custom shapes.

Here is a chart that shows how thickness, mesh size, and strand width change:

Use this chart to match mesh size to your project. Thick sheets with small holes are best for heavy things. Thin sheets with big holes are good for looks or letting air move.

Tip: Always measure the space for your sheet. Make sure the mesh size is safe and looks good.

The finish keeps your sheet safe and makes it look better. You can pick from different types:

Galvanized finish covers the sheet with zinc. This stops rust and is good for outside.

Powder-coated finish uses dry powder that is baked on. You can pick many colors. This finish stops scratches, rust, and sun damage.

Anodized finish adds a strong layer to aluminum. This makes the sheet stronger and stops rust.

Here is a table that shows how finishes help:

Finish Type | Description | Corrosion Resistance |

|---|---|---|

Powder-Coated Finish | Dry powder is baked on, comes in many colors. | Great at stopping rust, scratches, and sun. |

Anodized Finish | Makes aluminum thicker and stronger. | Stops rust and makes it stronger. |

Galvanized Finish | Zinc coating for better rust protection. | Good for outside and wet places. |

Tip: Pick a finish that matches where you will use the sheet. For outside, use galvanized or powder-coated. For inside, pick any finish you like.

When you pick Expanded Metal Sheets, think about how you will use them, what material is best, the right size and pattern, and the best finish. This helps you get a sheet that lasts, looks nice, and keeps people safe.

Now you understand how expanded metal sheets are used and why they are important. Think about what your project needs before picking a type or material. The table below lists main features to help you choose:

Mesh Type | Characteristics | Advantages | Common Uses |

|---|---|---|---|

Expanded Metal Mesh | Metal is cut and pulled to make diamond holes | It is strong and not heavy | Used for fences, walkways, safety, and building fronts |

If your project is special, talk to suppliers or experts. They can help you:

Learn about different material strengths

Find ways to change the sheet for your needs

Make sure the sheet fits your project’s use

Expanded metal has diamond-shaped holes. These holes are made by cutting and pulling the metal. Perforated metal has round or square holes. These holes are punched through the sheet. Expanded metal is stronger and makes less waste.

Yes, you can paint or coat expanded metal sheets. Powder coating, galvanizing, and anodizing are common ways to finish them. These finishes help stop rust and add color.

You can cut expanded metal sheets with tin snips. You can also use a hacksaw or an angle grinder. Always wear gloves and safety glasses. The edges are sharp and can cut you.

Expanded metal sheets work well outside. Pick aluminum, stainless steel, or galvanized steel for less rust. These materials last longer in rain and sun.