Hot Selling Stainless Steel Angel Iron Bar Equal Steel Angel Bar

Grade Stainless Steel

Shape Square

Tolerance ±1%

Steel Grade 301L, 301, 316L, 304, 304L, 301LN, 304J1

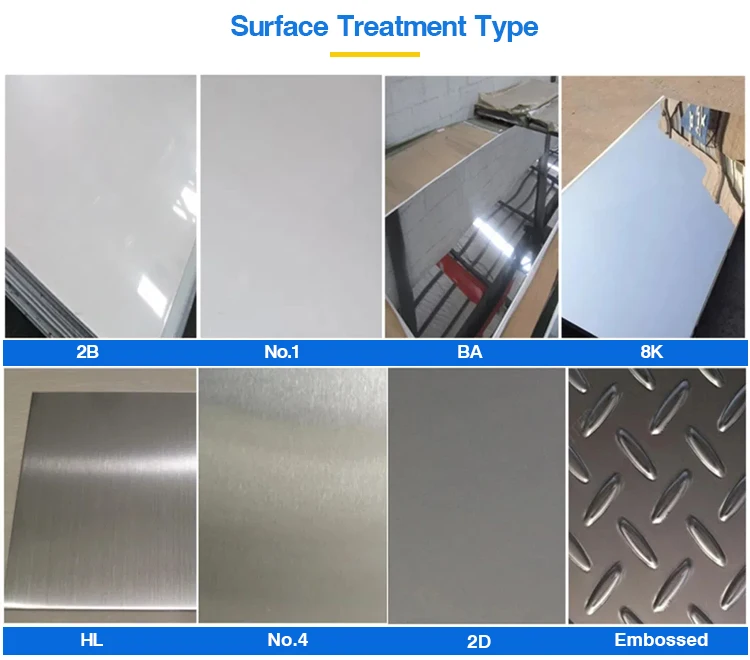

Surface Finish Customized

Delivery Time 22-30 days

Brand Name MingJun

Model Number 301 304

Type Round, Square, Hex

Application Construction

Special Use Valve Steels

Processing Service Bending, Welding, Decoiling, Punching, Cutting

Keyword Staninless Steel Bar

-

SHENGTENG

| Availability: | |

|---|---|

| PDF Export | |

Product Overview

TianJin ShengTeng Steel, a professional manufacturer specializing in steel products including steel pipes, galvanized pipes, steel sheets, and scaffolding products, proudly presents its hot-selling Stainless Steel Angel Iron Bar (Equal Angle). This product adheres to international standards such as A36 and ASTM, adopting the hot-rolled process to ensure excellent mechanical properties and structural stability. As a key product in the company’s steel portfolio, the equal angle steel bar features an L-shaped cross-section with equal leg lengths, making it a versatile choice for various structural and industrial applications. It is available in galvanized and non-galvanized options, with the galvanized version offering enhanced corrosion resistance to meet the demands of harsh environments. Whether for large-scale construction projects, machinery manufacturing, or home improvement, this stainless steel angel iron bar combines durability, cost-effectiveness, and ease of installation, making it a preferred choice for global customers seeking high-quality steel structural components.

Product Specifications

The Stainless Steel Angel Iron Bar (Equal Angle) from TianJin ShengTeng Steel is engineered to meet strict quality and size standards, with detailed specifications as shown in the table below:

Specification Category | Details |

Material Standard | A36, ASTM; High-quality mild steel (MS) with stable chemical composition and excellent mechanical performance |

Manufacturing Process | Hot-rolled; Ensures uniform material structure, high strength, and good ductility, avoiding defects such as internal cracks |

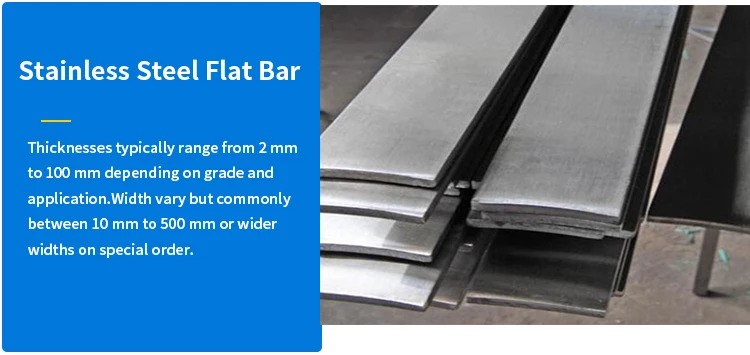

Cross-Section Type | Equal angle (L-profile); Leg lengths are equal, with common sizes ranging from 20mm×20mm to 200mm×200mm (custom sizes available upon request) |

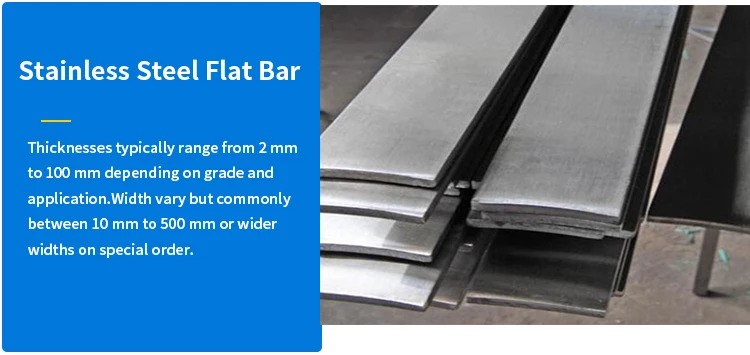

Thickness Range | 3mm - 20mm; Thickness uniformity is strictly controlled to ensure consistent load-bearing capacity across the entire bar |

Length | Standard lengths: 6m, 9m, 12m; Customized lengths (3m - 18m) available to meet specific project requirements |

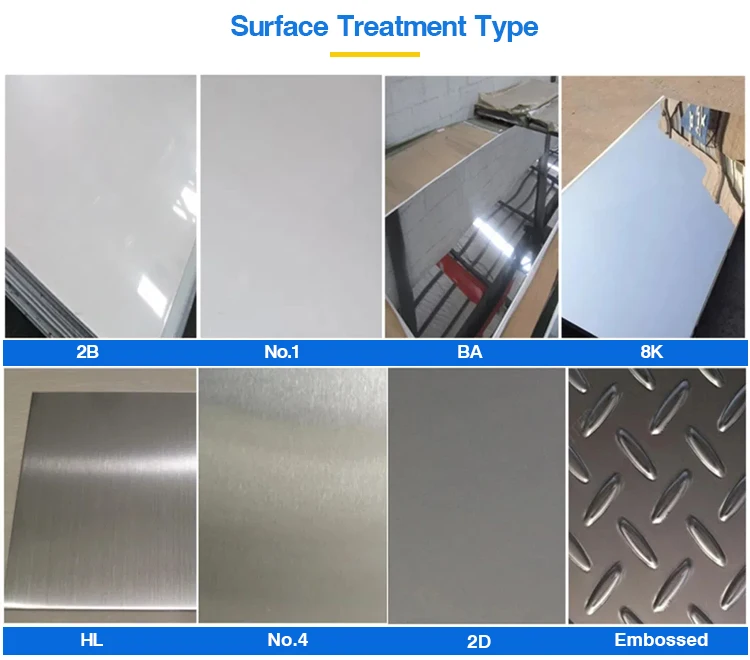

Surface Treatment | 1. Galvanized: Hot-dip galvanizing process, zinc coating thickness ≥ 85μm, providing strong resistance to rust and corrosion2. Non-galvanized: Black oxide finish, suitable for indoor or non-corrosive environments |

Mechanical Properties | Tensile strength: ≥400MPa; Yield strength: ≥250MPa; Elongation: ≥20% (tested in accordance with ASTM standards) |

Tolerance | Size tolerance complies with ASTM A6/A6M standards; Leg length tolerance: ±0.5mm, thickness tolerance: ±0.3mm |

Features

Superior Material and Process Quality

• The product is made of A36/ASTM-certified mild steel, which has undergone rigorous material testing to ensure no harmful impurities and stable chemical properties. This material foundation guarantees the bar’s long-term durability and resistance to deformation under heavy loads.

• The hot-rolled manufacturing process is a key advantage: compared with cold-rolled processes, hot rolling reduces internal stress in the steel, making the angel iron bar less prone to cracking or warping during cutting, welding, or installation. It also improves the material’s ductility, allowing for flexible processing into various shapes as needed.

Excellent Corrosion Resistance (Galvanized Version)

The galvanized stainless steel angel iron bar uses a hot-dip galvanizing process, where the steel bar is fully immersed in molten zinc to form a dense zinc coating. With a coating thickness of ≥85μm, this layer acts as a physical barrier against moisture, oxygen, and harmful chemicals in the environment. In tests, the galvanized version can resist rust for more than 10 years in outdoor environments (such as construction exteriors) and up to 20 years in indoor or low-corrosion environments (such as workshops), significantly extending the product’s service life and reducing maintenance costs for users.

Versatile and Easy to Install

• The equal L-profile design ensures balanced stress distribution, making the bar suitable for both load-bearing and non-load-bearing structural applications. Its symmetrical shape simplifies installation, as it can be easily aligned and fixed with bolts, welding, or rivets without complex adjustment.

• The product is available in a wide range of standard sizes (20mm×20mm to 200mm×200mm) and customizable lengths (3m - 18m), eliminating the need for excessive cutting or splicing in most projects. This not only saves time and labor costs but also reduces material waste, making it an eco-friendly and cost-effective choice.

Strict Quality Control

Every batch of stainless steel angel iron bars from TianJin ShengTeng Steel undergoes multi-stage quality inspection:

1. Raw material inspection: Checking the chemical composition and mechanical properties of the steel to ensure compliance with A36/ASTM standards.

2. Process inspection: Monitoring the temperature, speed, and pressure during the hot-rolling process to ensure uniform product thickness and shape.

3. Finished product inspection: Testing the tensile strength, yield strength, and elongation of random samples, as well as checking the surface finish and size tolerance. Only products that pass all inspections are allowed to leave the factory, ensuring that customers receive products of consistent and reliable quality.

Applications

Construction Industry

• Building Frames and Trusses: The equal angle steel bar is widely used in the construction of light steel frames, roof trusses, and wall supports. Its high tensile strength (≥400MPa) and stable load-bearing capacity ensure the structural safety of buildings, even in areas prone to strong winds or earthquakes.

• Scaffolding Components: As a key part of scaffolding systems, the product’s durability and easy installation make it ideal for temporary construction platforms. The galvanized version is particularly suitable for outdoor scaffolding, as it can withstand rain, snow, and other harsh weather conditions without rusting.

• Bridge and Highway Auxiliary Structures: It is used in the manufacturing of bridge guardrails, highway sound barriers, and drainage ditch supports. Its corrosion resistance and long service life reduce the frequency of maintenance and replacement, lowering the overall cost of infrastructure projects.

Machinery Manufacturing

• Equipment Frames and Supports: In the production of industrial machinery (such as conveyors, packaging machines, and printing equipment), the equal angle steel bar is used to build stable frames and supports. Its uniform thickness and precise size ensure that the machinery operates smoothly without vibration or deformation.

• Automotive and Shipbuilding Industries: It is used in the manufacturing of automotive chassis brackets and ship interior structural components. The product’s high ductility allows for easy welding and shaping, meeting the complex design requirements of these industries.

Home Improvement and Decoration

• Indoor and Outdoor Railings: The non-galvanized version (with a black oxide finish) is often used for indoor stair railings, while the galvanized version is suitable for outdoor balcony railings. Its sleek L-profile adds a modern touch to home decor, while its durability ensures long-term safety.

• Storage Racks and Shelves: It is used to build heavy-duty storage racks in garages, warehouses, or kitchens. The product’s load-bearing capacity (supporting up to 500kg per meter for large-size bars) makes it ideal for storing heavy items such as tools, appliances, and boxes.

FAQ

1. What is the difference between hot-rolled and cold-rolled equal angle steel bars?

Hot-rolled equal angle steel bars (like our product) are manufactured by heating steel to a high temperature (above 1000°C) and then rolling it into shape. This process results in a more uniform material structure, higher ductility, and lower internal stress, making the bars easier to weld and less prone to cracking. Cold-rolled bars, by contrast, are rolled at room temperature, which gives them a smoother surface finish but lower ductility and higher internal stress. For most structural applications (such as construction and machinery manufacturing), hot-rolled bars are preferred due to their superior mechanical properties and cost-effectiveness.

2. Can I request a custom size for the stainless steel angel iron bar?

Yes, TianJin ShengTeng Steel offers customized size services for the stainless steel angel iron bar. We can adjust the leg length (from 15mm×15mm to 250mm×250mm), thickness (from 2mm to 25mm), and length (from 3m to 18m) according to your specific project requirements. To ensure accuracy, we recommend providing detailed size drawings or specifications when placing a custom order. The lead time for custom orders is typically 7-15 days (depending on the order quantity and complexity), which is shorter than the industry average of 15-20 days.

3. How should I maintain the galvanized stainless steel angel iron bar to extend its service life?

The galvanized version of our product requires minimal maintenance, but the following steps can further extend its service life:

• Regular Cleaning: Use a soft cloth or brush to remove dust, dirt, or salt deposits (especially in coastal areas) from the surface. Avoid using abrasive cleaners, as they may scratch the zinc coating.

• Inspection for Damage: Check the surface for scratches, dents, or peeling of the zinc coating once every 6-12 months. If minor damage is found, apply a zinc-rich paint to the affected area to prevent rust.

• Avoid Contact with Corrosive Substances: Do not place the galvanized bars in direct contact with chemicals such as acids, alkalis, or strong solvents, as these can corrode the zinc coating. If used in industrial environments with corrosive fumes, consider adding a protective layer (such as a plastic film) to the surface.

4. Does TianJin ShengTeng Steel provide quality certificates for the stainless steel angel iron bar?

Yes, we provide a full set of quality certificates for every order, including ASTM A6/A6M certification (for size and mechanical properties), ISO 9001 quality management system certification (for production processes), and SGS test reports (for material composition and corrosion resistance). These certificates are issued by authoritative third-party testing institutions, ensuring that our products meet international quality standards. You can request these certificates before placing an order or receive them along with the goods upon delivery.

Product Overview

TianJin ShengTeng Steel, a professional manufacturer specializing in steel products including steel pipes, galvanized pipes, steel sheets, and scaffolding products, proudly presents its hot-selling Stainless Steel Angel Iron Bar (Equal Angle). This product adheres to international standards such as A36 and ASTM, adopting the hot-rolled process to ensure excellent mechanical properties and structural stability. As a key product in the company’s steel portfolio, the equal angle steel bar features an L-shaped cross-section with equal leg lengths, making it a versatile choice for various structural and industrial applications. It is available in galvanized and non-galvanized options, with the galvanized version offering enhanced corrosion resistance to meet the demands of harsh environments. Whether for large-scale construction projects, machinery manufacturing, or home improvement, this stainless steel angel iron bar combines durability, cost-effectiveness, and ease of installation, making it a preferred choice for global customers seeking high-quality steel structural components.

Product Specifications

The Stainless Steel Angel Iron Bar (Equal Angle) from TianJin ShengTeng Steel is engineered to meet strict quality and size standards, with detailed specifications as shown in the table below:

Specification Category | Details |

Material Standard | A36, ASTM; High-quality mild steel (MS) with stable chemical composition and excellent mechanical performance |

Manufacturing Process | Hot-rolled; Ensures uniform material structure, high strength, and good ductility, avoiding defects such as internal cracks |

Cross-Section Type | Equal angle (L-profile); Leg lengths are equal, with common sizes ranging from 20mm×20mm to 200mm×200mm (custom sizes available upon request) |

Thickness Range | 3mm - 20mm; Thickness uniformity is strictly controlled to ensure consistent load-bearing capacity across the entire bar |

Length | Standard lengths: 6m, 9m, 12m; Customized lengths (3m - 18m) available to meet specific project requirements |

Surface Treatment | 1. Galvanized: Hot-dip galvanizing process, zinc coating thickness ≥ 85μm, providing strong resistance to rust and corrosion2. Non-galvanized: Black oxide finish, suitable for indoor or non-corrosive environments |

Mechanical Properties | Tensile strength: ≥400MPa; Yield strength: ≥250MPa; Elongation: ≥20% (tested in accordance with ASTM standards) |

Tolerance | Size tolerance complies with ASTM A6/A6M standards; Leg length tolerance: ±0.5mm, thickness tolerance: ±0.3mm |

Features

Superior Material and Process Quality

• The product is made of A36/ASTM-certified mild steel, which has undergone rigorous material testing to ensure no harmful impurities and stable chemical properties. This material foundation guarantees the bar’s long-term durability and resistance to deformation under heavy loads.

• The hot-rolled manufacturing process is a key advantage: compared with cold-rolled processes, hot rolling reduces internal stress in the steel, making the angel iron bar less prone to cracking or warping during cutting, welding, or installation. It also improves the material’s ductility, allowing for flexible processing into various shapes as needed.

Excellent Corrosion Resistance (Galvanized Version)

The galvanized stainless steel angel iron bar uses a hot-dip galvanizing process, where the steel bar is fully immersed in molten zinc to form a dense zinc coating. With a coating thickness of ≥85μm, this layer acts as a physical barrier against moisture, oxygen, and harmful chemicals in the environment. In tests, the galvanized version can resist rust for more than 10 years in outdoor environments (such as construction exteriors) and up to 20 years in indoor or low-corrosion environments (such as workshops), significantly extending the product’s service life and reducing maintenance costs for users.

Versatile and Easy to Install

• The equal L-profile design ensures balanced stress distribution, making the bar suitable for both load-bearing and non-load-bearing structural applications. Its symmetrical shape simplifies installation, as it can be easily aligned and fixed with bolts, welding, or rivets without complex adjustment.

• The product is available in a wide range of standard sizes (20mm×20mm to 200mm×200mm) and customizable lengths (3m - 18m), eliminating the need for excessive cutting or splicing in most projects. This not only saves time and labor costs but also reduces material waste, making it an eco-friendly and cost-effective choice.

Strict Quality Control

Every batch of stainless steel angel iron bars from TianJin ShengTeng Steel undergoes multi-stage quality inspection:

1. Raw material inspection: Checking the chemical composition and mechanical properties of the steel to ensure compliance with A36/ASTM standards.

2. Process inspection: Monitoring the temperature, speed, and pressure during the hot-rolling process to ensure uniform product thickness and shape.

3. Finished product inspection: Testing the tensile strength, yield strength, and elongation of random samples, as well as checking the surface finish and size tolerance. Only products that pass all inspections are allowed to leave the factory, ensuring that customers receive products of consistent and reliable quality.

Applications

Construction Industry

• Building Frames and Trusses: The equal angle steel bar is widely used in the construction of light steel frames, roof trusses, and wall supports. Its high tensile strength (≥400MPa) and stable load-bearing capacity ensure the structural safety of buildings, even in areas prone to strong winds or earthquakes.

• Scaffolding Components: As a key part of scaffolding systems, the product’s durability and easy installation make it ideal for temporary construction platforms. The galvanized version is particularly suitable for outdoor scaffolding, as it can withstand rain, snow, and other harsh weather conditions without rusting.

• Bridge and Highway Auxiliary Structures: It is used in the manufacturing of bridge guardrails, highway sound barriers, and drainage ditch supports. Its corrosion resistance and long service life reduce the frequency of maintenance and replacement, lowering the overall cost of infrastructure projects.

Machinery Manufacturing

• Equipment Frames and Supports: In the production of industrial machinery (such as conveyors, packaging machines, and printing equipment), the equal angle steel bar is used to build stable frames and supports. Its uniform thickness and precise size ensure that the machinery operates smoothly without vibration or deformation.

• Automotive and Shipbuilding Industries: It is used in the manufacturing of automotive chassis brackets and ship interior structural components. The product’s high ductility allows for easy welding and shaping, meeting the complex design requirements of these industries.

Home Improvement and Decoration

• Indoor and Outdoor Railings: The non-galvanized version (with a black oxide finish) is often used for indoor stair railings, while the galvanized version is suitable for outdoor balcony railings. Its sleek L-profile adds a modern touch to home decor, while its durability ensures long-term safety.

• Storage Racks and Shelves: It is used to build heavy-duty storage racks in garages, warehouses, or kitchens. The product’s load-bearing capacity (supporting up to 500kg per meter for large-size bars) makes it ideal for storing heavy items such as tools, appliances, and boxes.

FAQ

1. What is the difference between hot-rolled and cold-rolled equal angle steel bars?

Hot-rolled equal angle steel bars (like our product) are manufactured by heating steel to a high temperature (above 1000°C) and then rolling it into shape. This process results in a more uniform material structure, higher ductility, and lower internal stress, making the bars easier to weld and less prone to cracking. Cold-rolled bars, by contrast, are rolled at room temperature, which gives them a smoother surface finish but lower ductility and higher internal stress. For most structural applications (such as construction and machinery manufacturing), hot-rolled bars are preferred due to their superior mechanical properties and cost-effectiveness.

2. Can I request a custom size for the stainless steel angel iron bar?

Yes, TianJin ShengTeng Steel offers customized size services for the stainless steel angel iron bar. We can adjust the leg length (from 15mm×15mm to 250mm×250mm), thickness (from 2mm to 25mm), and length (from 3m to 18m) according to your specific project requirements. To ensure accuracy, we recommend providing detailed size drawings or specifications when placing a custom order. The lead time for custom orders is typically 7-15 days (depending on the order quantity and complexity), which is shorter than the industry average of 15-20 days.

3. How should I maintain the galvanized stainless steel angel iron bar to extend its service life?

The galvanized version of our product requires minimal maintenance, but the following steps can further extend its service life:

• Regular Cleaning: Use a soft cloth or brush to remove dust, dirt, or salt deposits (especially in coastal areas) from the surface. Avoid using abrasive cleaners, as they may scratch the zinc coating.

• Inspection for Damage: Check the surface for scratches, dents, or peeling of the zinc coating once every 6-12 months. If minor damage is found, apply a zinc-rich paint to the affected area to prevent rust.

• Avoid Contact with Corrosive Substances: Do not place the galvanized bars in direct contact with chemicals such as acids, alkalis, or strong solvents, as these can corrode the zinc coating. If used in industrial environments with corrosive fumes, consider adding a protective layer (such as a plastic film) to the surface.

4. Does TianJin ShengTeng Steel provide quality certificates for the stainless steel angel iron bar?

Yes, we provide a full set of quality certificates for every order, including ASTM A6/A6M certification (for size and mechanical properties), ISO 9001 quality management system certification (for production processes), and SGS test reports (for material composition and corrosion resistance). These certificates are issued by authoritative third-party testing institutions, ensuring that our products meet international quality standards. You can request these certificates before placing an order or receive them along with the goods upon delivery.