- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

SHENGTENG

| Availability: | |

|---|---|

| PDF Export | |

Product details

| Brand name | SHENGTENG STEEL | |||

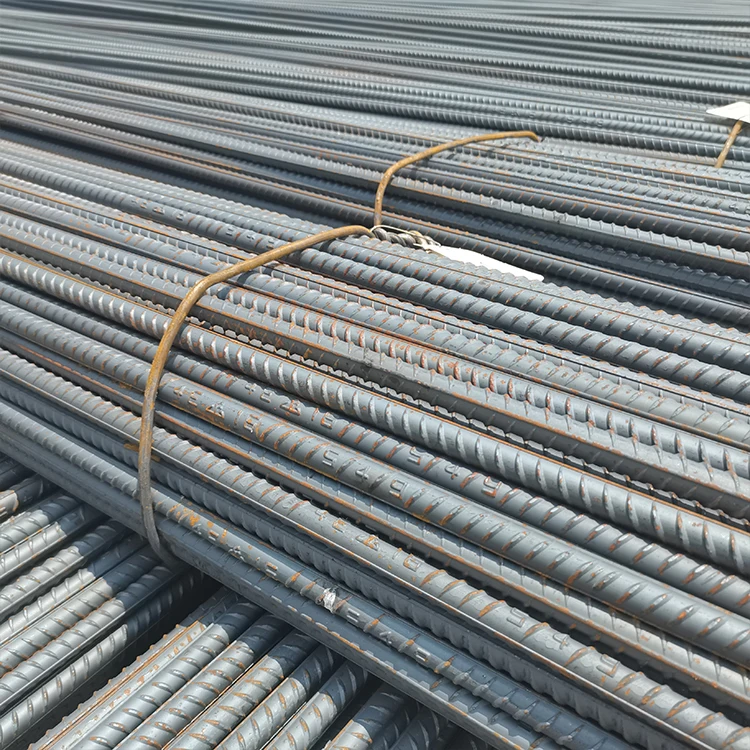

| Products name | steel rebar/iron rods/deformed Steel rebar reinforced carbon steel rebar | |||

| grade | HRB335/HRB400/HRB500,460B/B500A/B500B/B500C | |||

| size | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm,22mm,25mm,28mm,32mm,36mm,40mm,50mm | |||

| length | 6-12m or according to customer's requirement or in coil | |||

| Application | It is used in bridges, buildings, skyscrapers, homes, warehouses, and foundations to increase the strength of a concrete structure , Rebar is used in concrete to provide additional strength, as concrete is weak in tension, while steel is strong in both tension , and compression. | |||

| standard | GB1449-2007,BS4449-1997/2009,DIN488-4,BST500S,ASTM A615,GR40,GR60 ASTM A82 , ASTM A184/A184M , ASTM A185 ASTM A496, ASTM A497 , ASTM A615/A615M , ASTM A616/A616M , ASTM A617/A617M , ASTM A706/A706M , ASTM A722/A722M , ASTM A767/A767M , ASTM A775/A775M ASTM A934/A934M , ASTM A955, ASTM A996 , ASTM A1035 | |||

| package | packed in bundle or customer's requirement | |||

| Country of Origin | Tianjin.China | |||

The most common type of rebar is carbon steel, typically consisting of hot-rolled round bars with deformation patterns embossed into its surface. Steel and concrete have similar coefficients of thermal expansion , so a concrete structural member reinforced with steel will experience minimal differential stress as the temperature changes. Other readily available types of rebar are manufactured of stainless steel, and composite bars made of glass fiber, carbon fiber, or basalt fiber. The carbon steel reinforcing bars may also be coated in zinc or an epoxy resin designed to resist the effects of corrosion, especially when used in saltwater environments. Bamboo has been shown to be a viable alternative to reinforcing steel in concrete construction. These alternative types tend to be more expensive or may have lesser mechanical properties and are thus more often used in specialty construction where their physical characteristics fulfil a specific performance requirement that carbon steel does not provide.

FAQ

Product details

| Brand name | SHENGTENG STEEL | |||

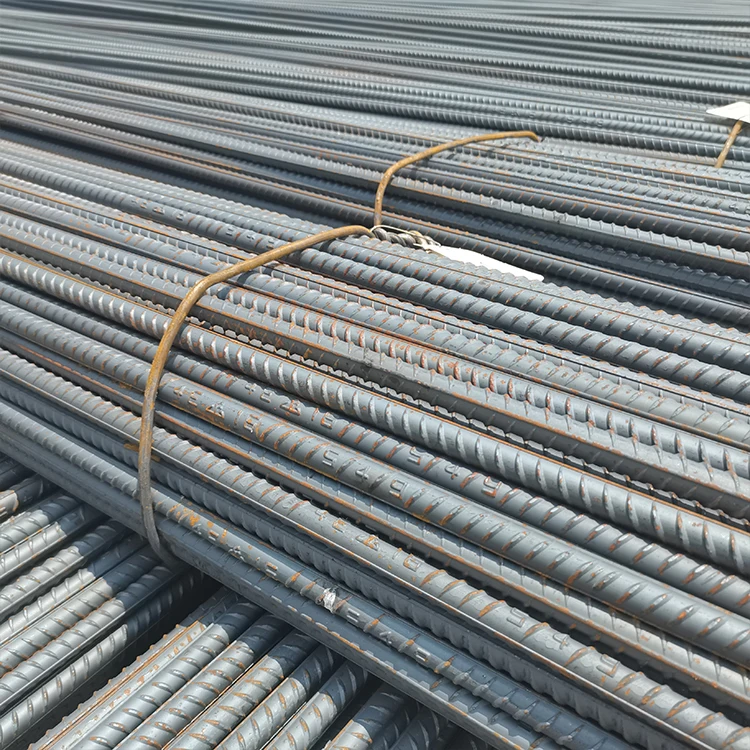

| Products name | steel rebar/iron rods/deformed Steel rebar reinforced carbon steel rebar | |||

| grade | HRB335/HRB400/HRB500,460B/B500A/B500B/B500C | |||

| size | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm,22mm,25mm,28mm,32mm,36mm,40mm,50mm | |||

| length | 6-12m or according to customer's requirement or in coil | |||

| Application | It is used in bridges, buildings, skyscrapers, homes, warehouses, and foundations to increase the strength of a concrete structure , Rebar is used in concrete to provide additional strength, as concrete is weak in tension, while steel is strong in both tension , and compression. | |||

| standard | GB1449-2007,BS4449-1997/2009,DIN488-4,BST500S,ASTM A615,GR40,GR60 ASTM A82 , ASTM A184/A184M , ASTM A185 ASTM A496, ASTM A497 , ASTM A615/A615M , ASTM A616/A616M , ASTM A617/A617M , ASTM A706/A706M , ASTM A722/A722M , ASTM A767/A767M , ASTM A775/A775M ASTM A934/A934M , ASTM A955, ASTM A996 , ASTM A1035 | |||

| package | packed in bundle or customer's requirement | |||

| Country of Origin | Tianjin.China | |||

The most common type of rebar is carbon steel, typically consisting of hot-rolled round bars with deformation patterns embossed into its surface. Steel and concrete have similar coefficients of thermal expansion , so a concrete structural member reinforced with steel will experience minimal differential stress as the temperature changes. Other readily available types of rebar are manufactured of stainless steel, and composite bars made of glass fiber, carbon fiber, or basalt fiber. The carbon steel reinforcing bars may also be coated in zinc or an epoxy resin designed to resist the effects of corrosion, especially when used in saltwater environments. Bamboo has been shown to be a viable alternative to reinforcing steel in concrete construction. These alternative types tend to be more expensive or may have lesser mechanical properties and are thus more often used in specialty construction where their physical characteristics fulfil a specific performance requirement that carbon steel does not provide.

FAQ