SHENGTENG Copper Alloy MIG Solid Welding Wire MIG Welding Wire 0.8mm 0.9mm 1.2mm Co2 Welding Wire ER70S-6

Diameter 0.8 0.9 1.0 1.2

Melting Point 1000℃

Weight 15KG or 20KG /SPOOL

Flux Content NO

Customized support OEM, ODM

Brand Name HUARUI

Model Number ER70S-6

Application LOW CARBON STEEL

Product name Mig Welding Wire ER70S-6

Application carbon steel and low alloy steel

Material carbon steel

Package plastic spoool metal spool drum

MOQ 1000KG

Standard ER70S-6

Diameter 0.6-2.0mm

Weight 15kg 20kg 250kg 350kg

-

SHENGTENG

| Availability: | |

|---|---|

| PDF Export | |

Features:

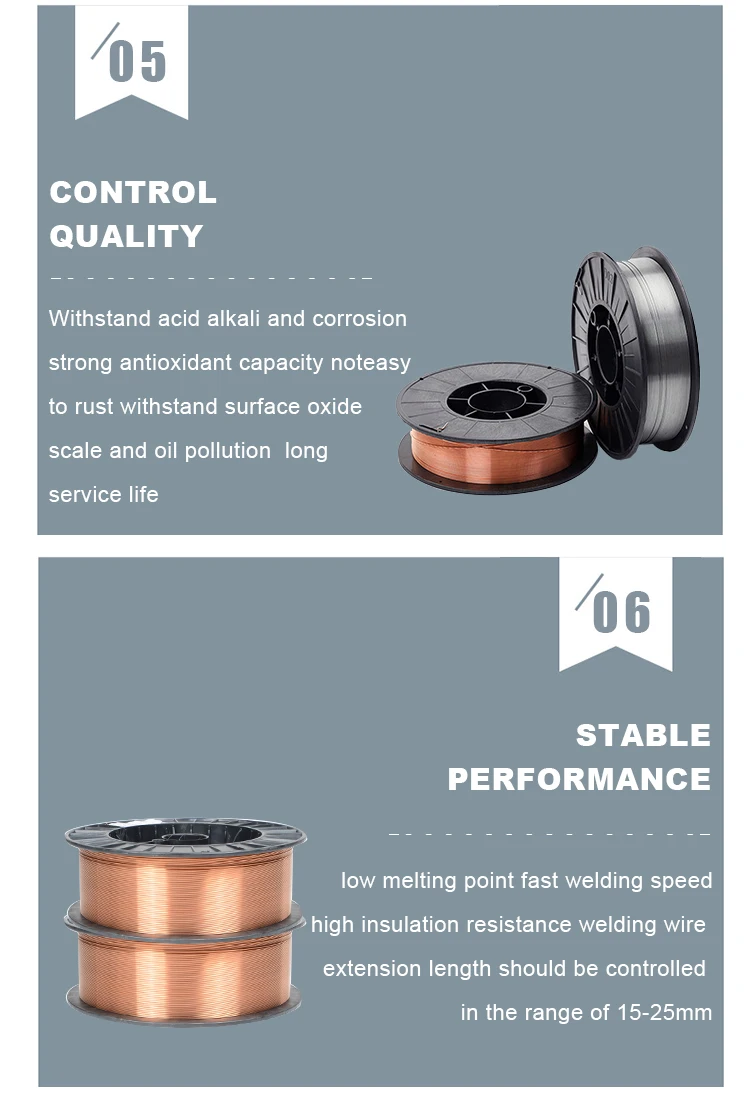

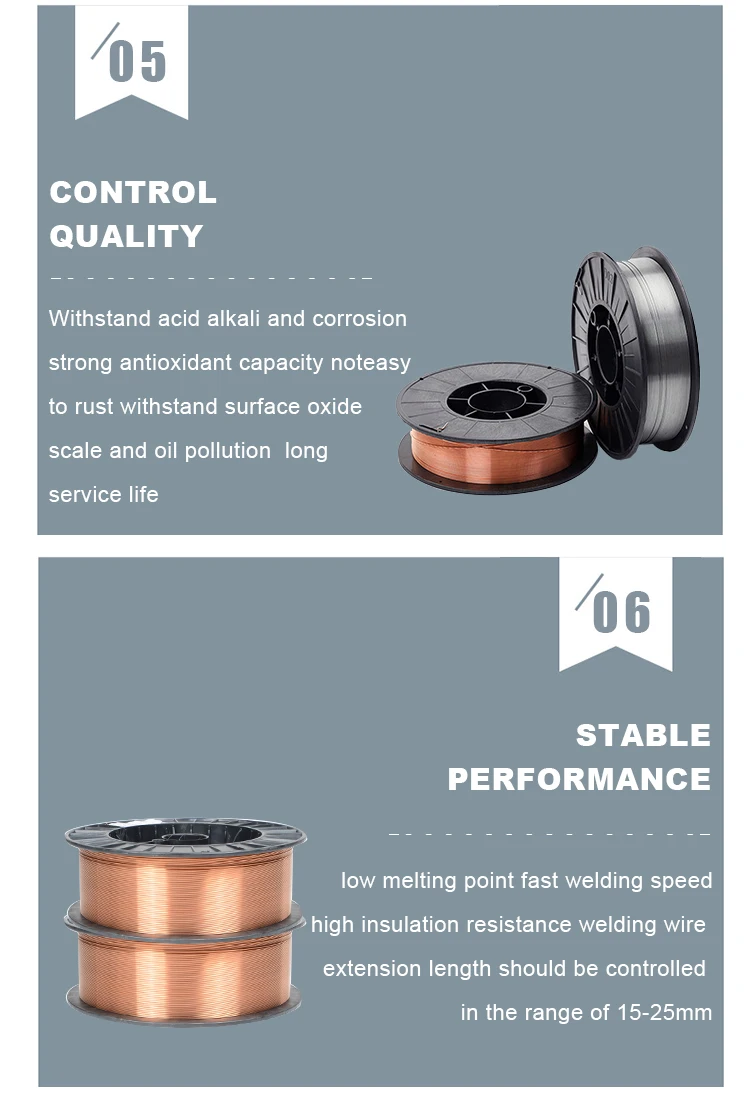

ER70S-6 is a kind of mild steel copper coated welding wire, suitable for 100% CO2 and Argon& CO2 mixed gas protective welding with stable feasibility, good welding seams, less spatters and excellent welding process properties.

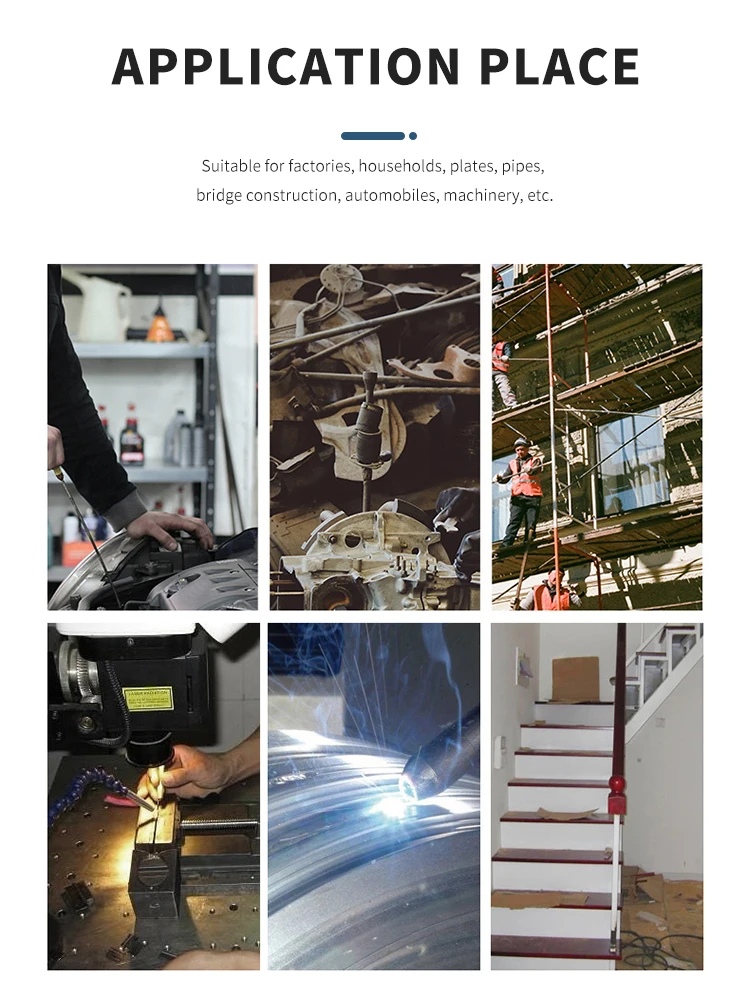

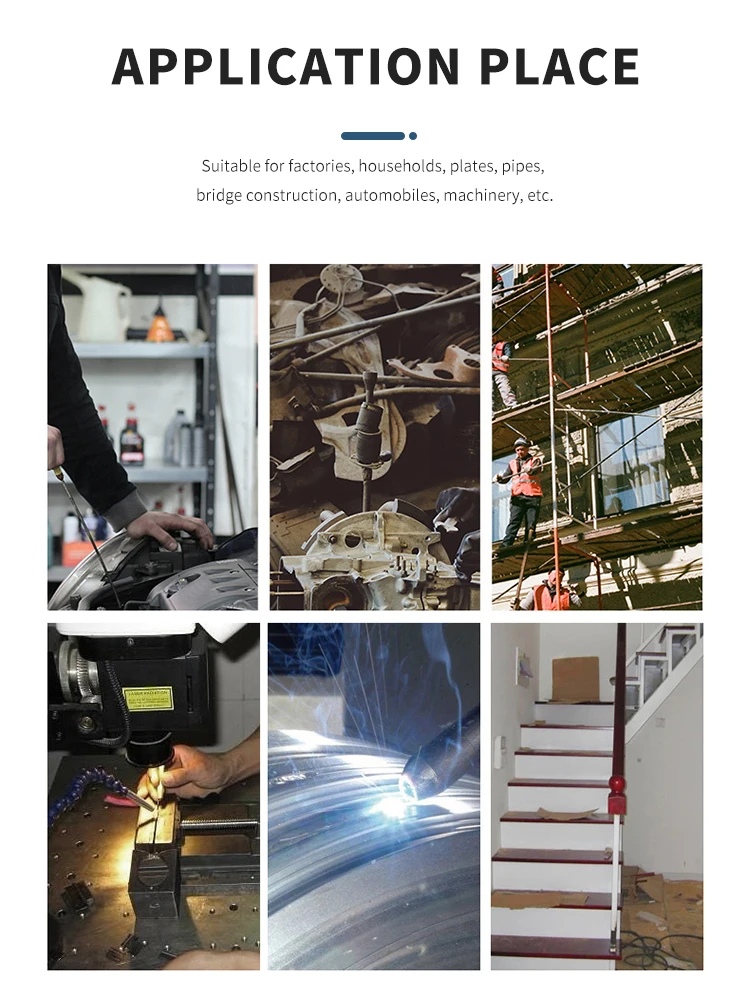

Application:

Used to weld ship building steel(A,B,D,E,A36,D36,E36)and equivalent mild steel or 550Mpa grade mild alloy steel, such as container building, construction machine, railway construction, pressure vessel for semi-auto or automatic gas shielded welding.

| Wire Chemical Composition(%) | C | Mn | Si | P | S | Cr | Ni | Cu |

| 0.06~0.15 | 1.40~1.85 | 0.80~1.15 | ≤0.025 | ≤0.025 | ≤0.15 | ≤0.15 | ≤0.50 |

| Deposited Metal Mechanical Properties | Yield Strength σ0.2(Mpa) | Tensile Strength σb(Mpa) | Elongation δ5% | AKV Impact Energy (J)(-30℃) |

| ≥420 | ≥500 | ≥22 | ≥27 |

| Diameter of Wire(mm) | Φ0.8 | Φ1.0 | Φ1.2 | Φ1.6 |

| Welding Current(A) | 50-180 | 70-230 | 80~350 | 80-500 |

| Matters needing attention: | ||||

| 1. Wire into the plant must be stored in dry conditions, can not open welding wire coil waterproof packaging. 2. Welding shall be removed before welding surface oil, rust, water and other impurities. 3. The CO2 gas protection, CO2 gas purity 99.98%. 4. CO2 welding protective gas flow rate should be controlled at 20~25L/min. 5. Wire extension length should be controlled in the range of 15~25mm. | ||||

A:Sure,we can supply samples. For regular goods, the sample cost is different from the amount you want. For our new products,there's a MOQ of the samples.

Q2: Can I put my logo on the boxes/cartons?

A: Yes, this can be made according to your requirements, but you should send us the trademark authorization letter.Q3: How can you guarantee your products quality ?

A: Huarui's each torch must pass the following tests before packing: Insulation resistance test, High voltage test, Air/Water flowtest, Air/Water seal test.If there are defective items, we usually credit to our customer or replace in the next shipment.Q4: What's the order procedure?

A: Firstly, we discuss the details together by e-mail or TM. Then we issue you a PI for your confirmation or Trade Assurance OrderPayment Link. You will be requested to do the pre-paid full payment before we go into the production. After we get the payment, westart to process the order. It usually takes 5-15days if we don't have the items in stock.

Features:

ER70S-6 is a kind of mild steel copper coated welding wire, suitable for 100% CO2 and Argon& CO2 mixed gas protective welding with stable feasibility, good welding seams, less spatters and excellent welding process properties.

Application:

Used to weld ship building steel(A,B,D,E,A36,D36,E36)and equivalent mild steel or 550Mpa grade mild alloy steel, such as container building, construction machine, railway construction, pressure vessel for semi-auto or automatic gas shielded welding.

| Wire Chemical Composition(%) | C | Mn | Si | P | S | Cr | Ni | Cu |

| 0.06~0.15 | 1.40~1.85 | 0.80~1.15 | ≤0.025 | ≤0.025 | ≤0.15 | ≤0.15 | ≤0.50 |

| Deposited Metal Mechanical Properties | Yield Strength σ0.2(Mpa) | Tensile Strength σb(Mpa) | Elongation δ5% | AKV Impact Energy (J)(-30℃) |

| ≥420 | ≥500 | ≥22 | ≥27 |

| Diameter of Wire(mm) | Φ0.8 | Φ1.0 | Φ1.2 | Φ1.6 |

| Welding Current(A) | 50-180 | 70-230 | 80~350 | 80-500 |

| Matters needing attention: | ||||

| 1. Wire into the plant must be stored in dry conditions, can not open welding wire coil waterproof packaging. 2. Welding shall be removed before welding surface oil, rust, water and other impurities. 3. The CO2 gas protection, CO2 gas purity 99.98%. 4. CO2 welding protective gas flow rate should be controlled at 20~25L/min. 5. Wire extension length should be controlled in the range of 15~25mm. | ||||

A:Sure,we can supply samples. For regular goods, the sample cost is different from the amount you want. For our new products,there's a MOQ of the samples.

Q2: Can I put my logo on the boxes/cartons?

A: Yes, this can be made according to your requirements, but you should send us the trademark authorization letter.Q3: How can you guarantee your products quality ?

A: Huarui's each torch must pass the following tests before packing: Insulation resistance test, High voltage test, Air/Water flowtest, Air/Water seal test.If there are defective items, we usually credit to our customer or replace in the next shipment.Q4: What's the order procedure?

A: Firstly, we discuss the details together by e-mail or TM. Then we issue you a PI for your confirmation or Trade Assurance OrderPayment Link. You will be requested to do the pre-paid full payment before we go into the production. After we get the payment, westart to process the order. It usually takes 5-15days if we don't have the items in stock.