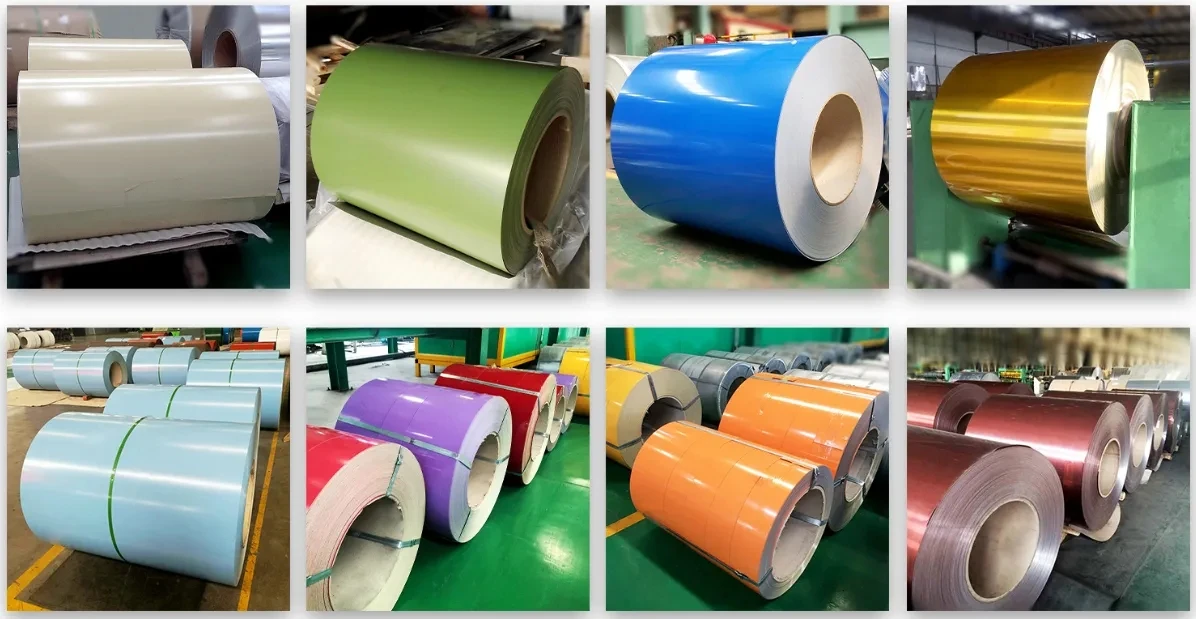

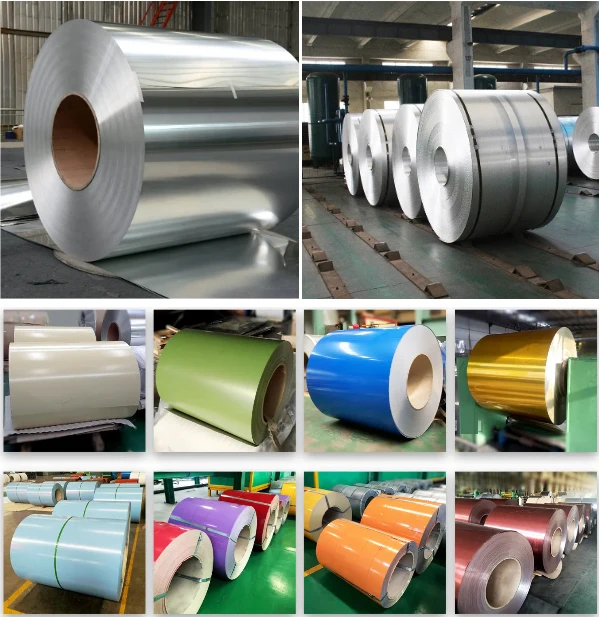

PPGI Coils Color Coated Steel Coil Prepainted Galvanized Steel Coil Z275/Metal Roofing Sheets Building Materials In China

Coating Z30-Z40

Grade DX51D, SGCC, G550, S550, S350, ECTS.

Delivery Time within 7 days

Width 500-1250mm

Length According to your needs

Certificate ISO9001

Tolerance ±1%

-

SHENGTENG

| Availability: | |

|---|---|

| PDF Export | |

Products Description

PPGI Coils Color Coated Steel Coil Prepainted Galvanized Steel Coil Z275/Metal Roofing Sheets Building Materials In China

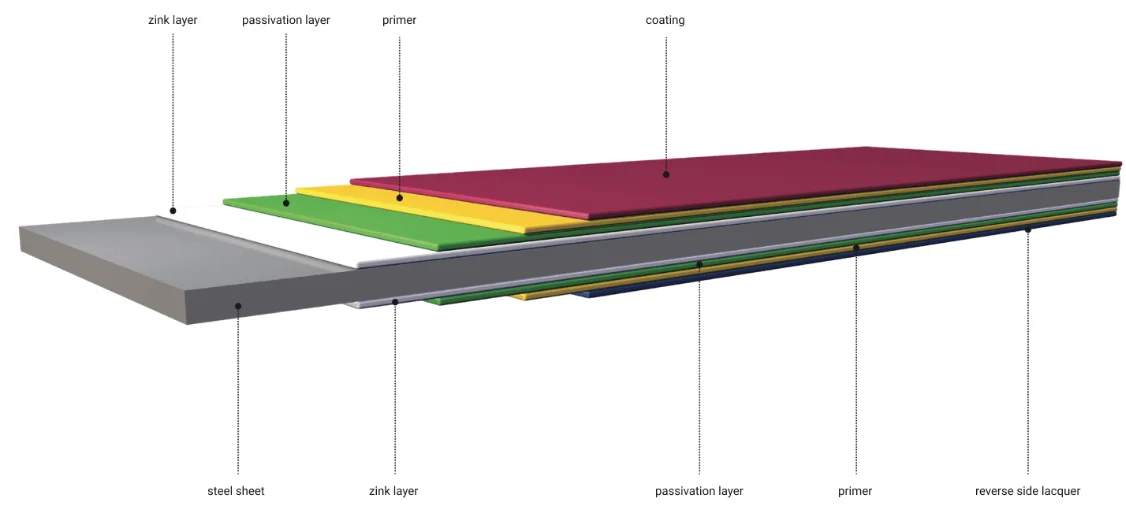

Galvanized steel is to prevent the steel plate surface from corrosion to extend its service life, in the steel plate surface coated with a layer of metal zinc, the zinc coated steel plate are called galvanized sheet. According to the production and processing methods can be divided into the:

Hot dip galvanized steel

Thin plate in melting zinc bath, make its surface adhesion of a layer of zinc sheet. At present mainly adopts continuous galvanizing process, namely the continuous roll of steel plate in the melt zinc plating tank made of galvanized steel sheet;

The alloying of galvanized steel

This kind of steel plate is made by hot dip method, but after the slot, immediately heated to a temperature of about 500 ℃, it make the generation of zinc and iron alloy membrane. This kind of galvanized sheet with good coating of sex and weldability;

Product Parameters

| Technical Standard | EN10147/EN10142/DIN 17162/JIS G3302/ASTM A653 |

| Steel Grade | DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ, SECC,SECE, BLCE+Z, BLDE+Z, BUSDE+Z or Customer’s Requirement |

| Base Steel | Hot dip galvanized steel, Hot dip galvalume steel, Electro galvanized steel |

| Thickness | 0.12-6.0mm |

| Width | 600-1500mm |

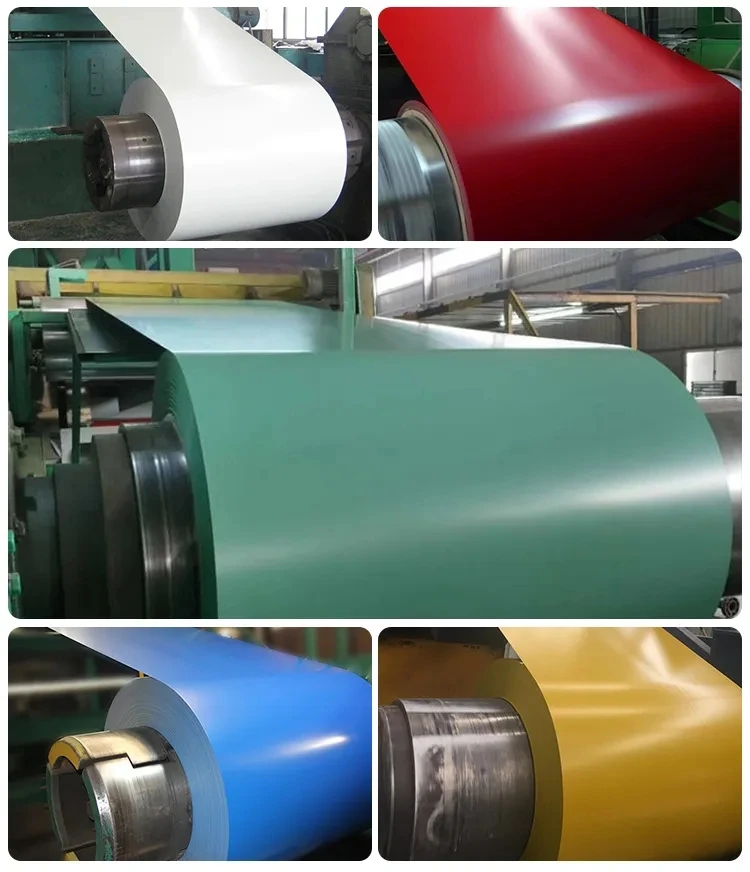

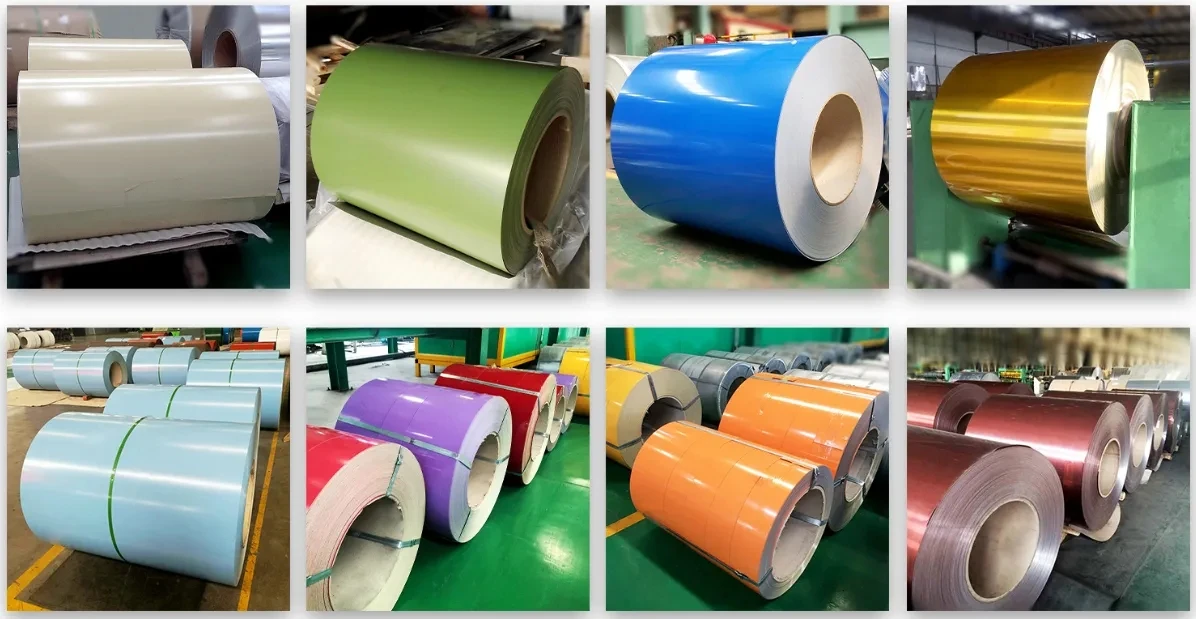

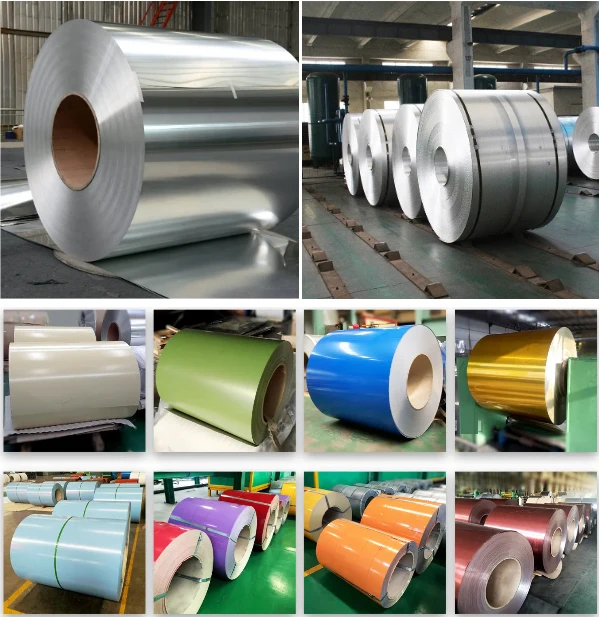

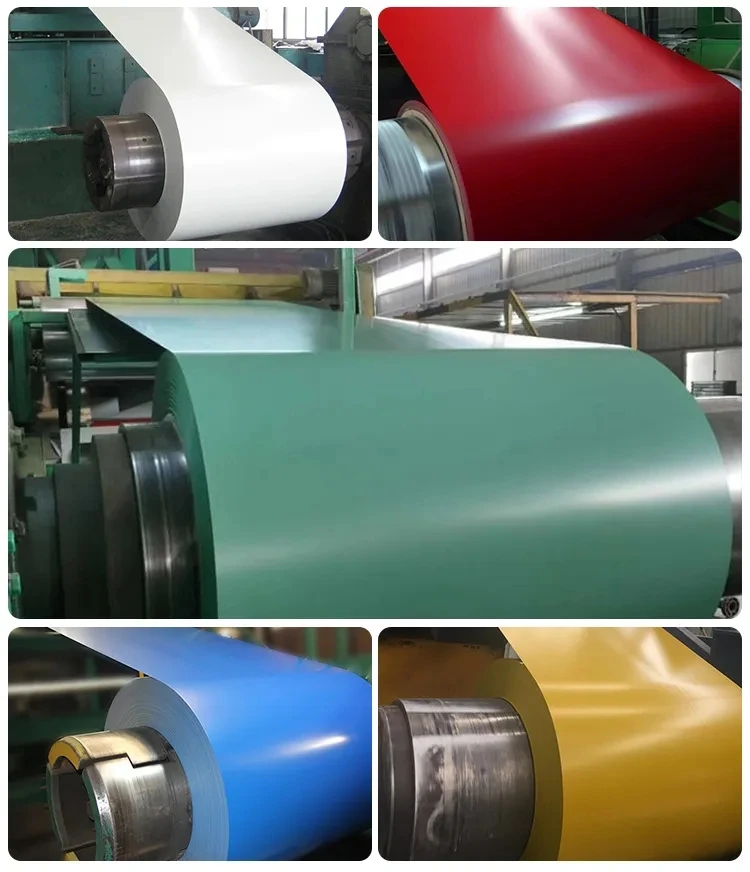

| Surface Color | RAL,wood grain pattern, camouflage pattern , stone pattern, matte pattern , high gloss pattern , flower pattern, etc |

| Quality | Approved by SGS,ISO |

| Coil Weight | 3-20metric ton per coil |

| Package | Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by seven steel belt.or according to customer's requirement |

| Export market | Europe,Africa,Central Asia,Southeast Asia,Middle East,South America,North America, etc |

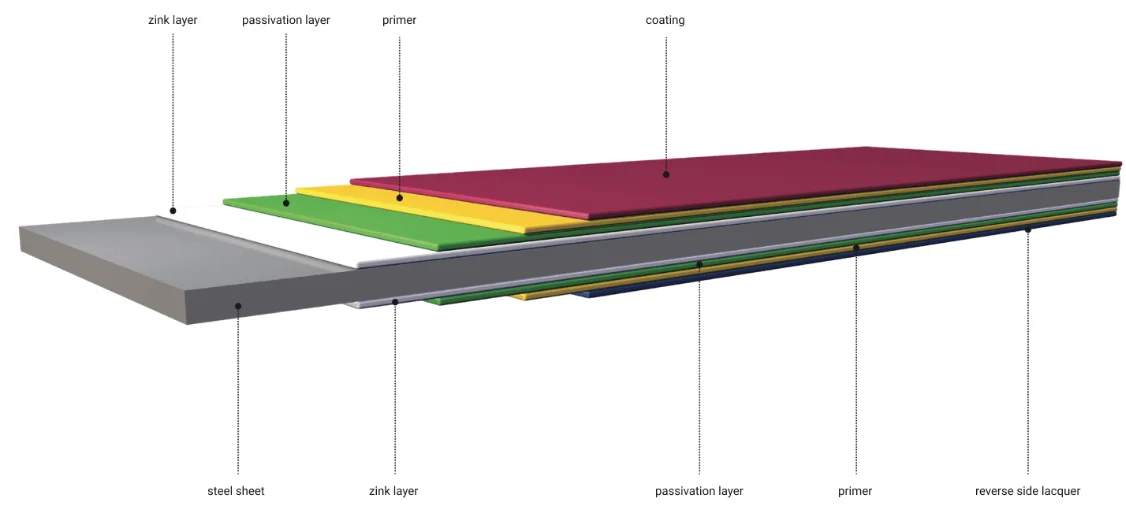

PPGI & PPGL (prepainted galvanized steel & prepainted galvalume steel) also known as pre-coated steel or color coated steel coil,It is a product made of hot-dip galvanized steel sheet, hot-dip galvalume steel sheet, electro galvanized steel sheet, etc. After surface pretreatment, one or several layers of organic coating are applied on the surface, and then baked and solidified. The color coated steel coil is light in weight, beautiful in appearance, and has good anti-corrosion performance, and can be directly processed. The color is generally divided into gray, sea blue, brick red, etc. It is mainly used in advertising, construction,decoration, home appliances, electrical appliances, Furniture industry and transportation industry. The coatings used for color coated steel coils are based on the environment in which the resin is selected, such as polyester silicon modified polyester,polyvinyl chloride plastisol, polyvinylidene chloride, and the like.

![]()

Product Advantages

Excellent Durability & Corrosion Resistance

The color-coated steel strip, using hot-dip galvanized steel as its base, combines the dual protection of a zinc layer and an organic coating. This structure significantly enhances corrosion resistance, offering a service life approximately 1.5 times longer than regular galvanized steel.Outstanding Heat Resistance

Maintains stability under high temperatures with minimal risk of discoloration, making it ideal for environments with fluctuating heat levels.Superior Reflectivity & Weldability

Features high heat reflectivity and reliable weldability, ensuring both energy efficiency and ease of fabrication in construction processes.High Cost-Performance Ratio

Combines long service life with economical value, making it a preferred choice for industrial buildings, steel structures, and civil construction applications.

Chemical Composition

Galvanized Steel 0.18mm-20mm thick galvanized steel sheet 2mm thick Hot dip galvanized steel sizes galvanized sheet metal roll| bse metal type | Grade | CHEMICAL COMPOSITION % | ||||

| C | Si | Mn | P | S | ||

| cold rolled steel sheet | DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | ≤0.10 | - | ≤0.50 | ≤0.035 | 0.03 |

| DC52D+Z (St04Z), DC52D+ZF | ≤0.08 | - | ≤0.45 | ≤0.030 | 0.03 | |

| DC53D+Z (St05Z), DC53D+ZF | ≤0.08 | - | ≤0.40 | ≤0.030 | 0.03 | |

| DC54D+Z (St06Z), DC54D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | 0.03 | |

| DC56D+Z (St07Z), DC56D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | 0.03 | |

| hot rolled steel sheet | DD51D+Z (St01ZR, St02ZR) | ≤0.10 | - | ≤0.50 | ≤0.035 | 0.03 |

| DD54D+Z (St06ZR) | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | 0.03 | |

Substrate Types

Hot-Dip Galvanized Color Coated Steel Sheet

(Prepainted Galvanized Steel Sheet)

This product is made by applying an organic coating over hot-dip galvanized steel. In addition to the corrosion protection provided by the zinc layer, the organic coating offers an additional barrier against rust. As a result, it has a longer service life compared to standard hot-dip galvanized sheets.Hot-Dip Aluzinc Color Coated Steel Sheet

(Prepainted Galvalume Steel Sheet)

Hot-dip Aluzinc substrates, typically composed of 55% aluminum and 45% zinc (or 5% AI-Zn variants), can also be used for color-coated applications. These sheets offer excellent corrosion resistance and thermal reflectivity.Electro-Galvanized Color Coated Steel Sheet

(Prepainted Electro-Galvanized Steel Sheet)

Produced by applying an organic coating to electro-galvanized steel, this type features a smooth surface finish, attractive appearance, and excellent formability. It is widely used in applications such as home appliances, audio equipment, steel furniture, and interior decoration.

Types of Colour Coating

Standard Polyester (PE)

Good gloss retention, color stability, and cost-effectiveness; suitable for general-purpose applications.Matt Polyester

Offers a soft, non-reflective surface with enhanced aesthetic appeal; ideal for architectural projects.Decoprint

A printed decorative coating that simulates textures such as wood grain or stone; commonly used for indoor decoration and high-end finishes.

Coating Types

Polyester (PE)

Offers good adhesion and a wide range of vibrant colors. Known for its excellent formability and decent outdoor durability. It provides medium chemical resistance at a relatively low cost, making it suitable for general-purpose applications.Silicon Modified Polyester (SMP)

Provides good abrasion and heat resistance. Features improved durability and resistance to chalking and fading in outdoor environments. Maintains moderate gloss retention and flexibility, with a medium price point.High Durability Polyester (HDP)

Delivers excellent color retention and UV resistance. Ideal for harsh outdoor conditions thanks to its strong resistance to chalking and weathering. Offers superior paint film adhesion, vibrant color options, and outstanding cost performance.Polyvinylidene Fluoride (PVDF)

Known for top-tier color retention and exceptional resistance to UV rays and weathering. Exhibits excellent solvent resistance, stain resistance, and chalking resistance. Offers good formability, though available in limited color ranges and at a higher cost.

The Production Process

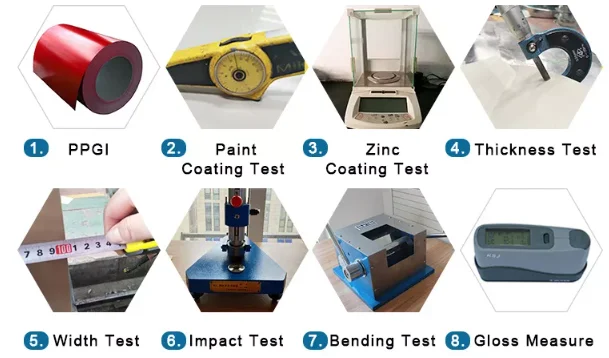

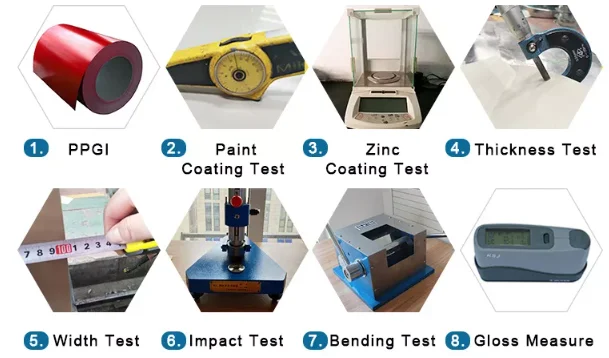

Product Testing

PPGI

(Prepainted galvanized steel coil or sheet)Paint Coating Test

Measures the thickness and uniformity of the paint layer.Zinc Coating Test

Evaluates the zinc layer weight and consistency.Thickness Test

Verifies overall material thickness using a micrometer.Width Test

Ensures dimensional accuracy across coil or sheet width.Impact Test

Assesses the coating’s ability to resist impact without cracking or detaching.Bending Test

Checks the flexibility of the coated steel during bending without peeling or cracking.Gloss Measure

Evaluates surface gloss to meet visual or decorative standards.

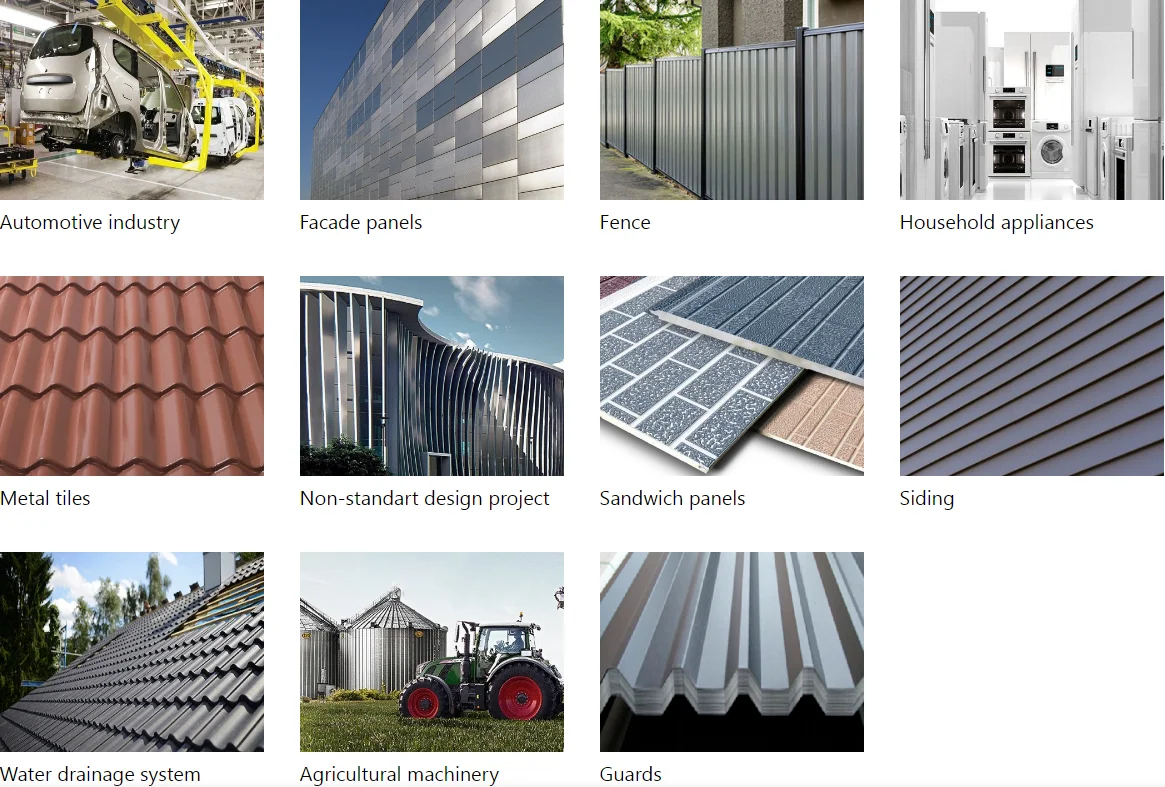

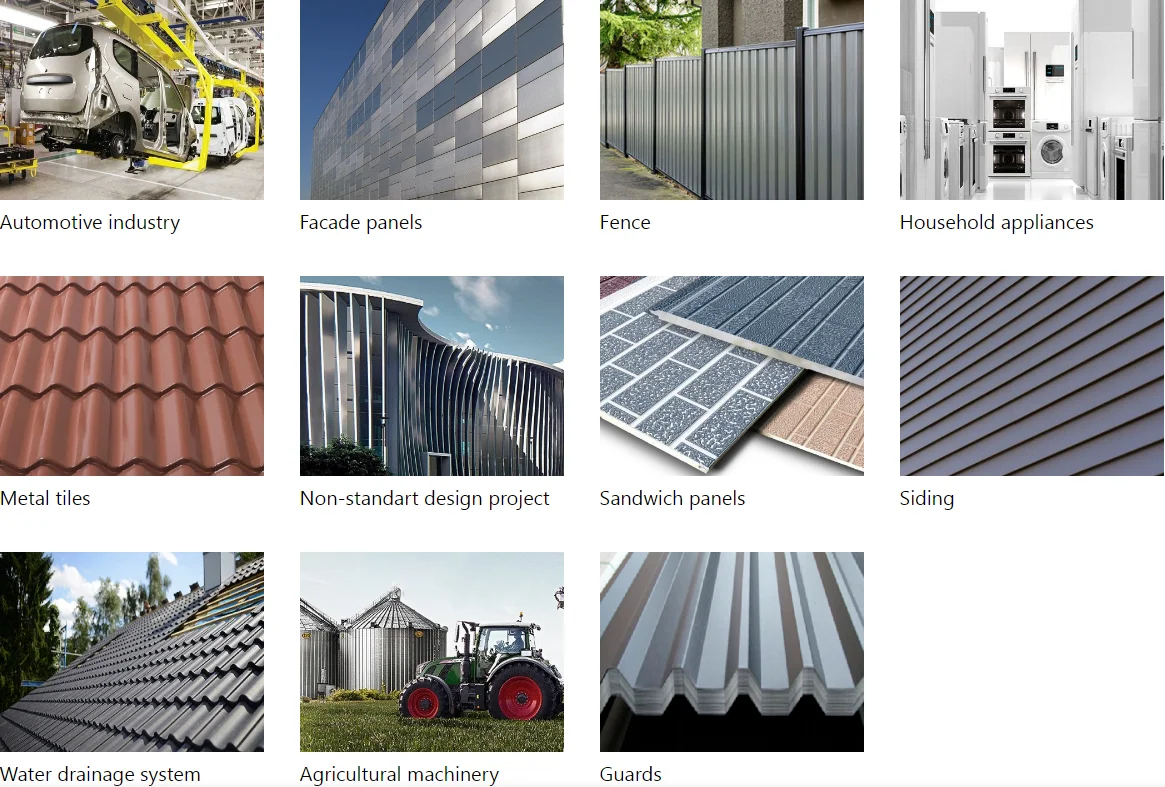

Product Application

Automotive industry

Facade panels

Fence

Household appliances

Metal tiles

Non-standard design project

Sandwich panels

Siding

Water drainage system

Agricultural machinery

Guards

(1)In the construction industry: to manufacture exterior and Interior products such as metal shingles, corrugated sheeting, sandwich panels, profiles, metallic ceilings, skirting boards, decorative panels inside heated and non- heated rooms, elevators, doors window shutters, shelves etc.

(2)In the automotive industry: to manufacture external and internal car body parts (car doors, car boots, oil filters, dashboards, windscreen wipers etc.

(3)In manufacture of home appliances, furniture, and consumer goods: metallic furniture, lighting equipment, shelves, radiators, сar doors, car boots etc.

FAQ

1.Will you deliver the goods on time?

Yes,we promise to provide best quality products and delivery in time no matter if the price change lot or not, Honesty is our company's tenet.

2.How can I get your quotation as soon as possible?

The email and fax will be checked in 24 hours, meanwhile, the skype will be online in 24 hours Please tell us the order information about quantity, Specification(steel type, material, size )and destination port, you will get the latest price.

3.How about the sample if i need?

The sample will be offered for free if you need, but the freight will be covered by our customer. If we have cooperation, the freight will be covered by our company.

4.How about the MOQ?

Generally, the trail order will be accepted.The MOQ can be confirmed according to the different products. For example, the MOQ of PPGI will be 10MT.

5.How about the delivery time?

Within 15-30days after receiving the deposit or L/C at sight. Of course, the detail will be confirmed by the quantity and the different products.

6.How to order?

Please send us your purchase order by email. Or you can ask us to send you a proforma invoice for your order. We need to know the following information for your order.

7.What is shipment terms?

1. Container ship 2. bulk ship 3. Train

8.Do you have English Mill Test Certificates?

Yes,that is what we give gurantee to our clients9.Do you accept the third party inspection?Yes,absolutely we accept.

Products Description

PPGI Coils Color Coated Steel Coil Prepainted Galvanized Steel Coil Z275/Metal Roofing Sheets Building Materials In China

Galvanized steel is to prevent the steel plate surface from corrosion to extend its service life, in the steel plate surface coated with a layer of metal zinc, the zinc coated steel plate are called galvanized sheet. According to the production and processing methods can be divided into the:

Hot dip galvanized steel

Thin plate in melting zinc bath, make its surface adhesion of a layer of zinc sheet. At present mainly adopts continuous galvanizing process, namely the continuous roll of steel plate in the melt zinc plating tank made of galvanized steel sheet;

The alloying of galvanized steel

This kind of steel plate is made by hot dip method, but after the slot, immediately heated to a temperature of about 500 ℃, it make the generation of zinc and iron alloy membrane. This kind of galvanized sheet with good coating of sex and weldability;

Product Parameters

| Technical Standard | EN10147/EN10142/DIN 17162/JIS G3302/ASTM A653 |

| Steel Grade | DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ, SECC,SECE, BLCE+Z, BLDE+Z, BUSDE+Z or Customer’s Requirement |

| Base Steel | Hot dip galvanized steel, Hot dip galvalume steel, Electro galvanized steel |

| Thickness | 0.12-6.0mm |

| Width | 600-1500mm |

| Surface Color | RAL,wood grain pattern, camouflage pattern , stone pattern, matte pattern , high gloss pattern , flower pattern, etc |

| Quality | Approved by SGS,ISO |

| Coil Weight | 3-20metric ton per coil |

| Package | Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by seven steel belt.or according to customer's requirement |

| Export market | Europe,Africa,Central Asia,Southeast Asia,Middle East,South America,North America, etc |

PPGI & PPGL (prepainted galvanized steel & prepainted galvalume steel) also known as pre-coated steel or color coated steel coil,It is a product made of hot-dip galvanized steel sheet, hot-dip galvalume steel sheet, electro galvanized steel sheet, etc. After surface pretreatment, one or several layers of organic coating are applied on the surface, and then baked and solidified. The color coated steel coil is light in weight, beautiful in appearance, and has good anti-corrosion performance, and can be directly processed. The color is generally divided into gray, sea blue, brick red, etc. It is mainly used in advertising, construction,decoration, home appliances, electrical appliances, Furniture industry and transportation industry. The coatings used for color coated steel coils are based on the environment in which the resin is selected, such as polyester silicon modified polyester,polyvinyl chloride plastisol, polyvinylidene chloride, and the like.

![]()

Product Advantages

Excellent Durability & Corrosion Resistance

The color-coated steel strip, using hot-dip galvanized steel as its base, combines the dual protection of a zinc layer and an organic coating. This structure significantly enhances corrosion resistance, offering a service life approximately 1.5 times longer than regular galvanized steel.Outstanding Heat Resistance

Maintains stability under high temperatures with minimal risk of discoloration, making it ideal for environments with fluctuating heat levels.Superior Reflectivity & Weldability

Features high heat reflectivity and reliable weldability, ensuring both energy efficiency and ease of fabrication in construction processes.High Cost-Performance Ratio

Combines long service life with economical value, making it a preferred choice for industrial buildings, steel structures, and civil construction applications.

Chemical Composition

Galvanized Steel 0.18mm-20mm thick galvanized steel sheet 2mm thick Hot dip galvanized steel sizes galvanized sheet metal roll| bse metal type | Grade | CHEMICAL COMPOSITION % | ||||

| C | Si | Mn | P | S | ||

| cold rolled steel sheet | DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | ≤0.10 | - | ≤0.50 | ≤0.035 | 0.03 |

| DC52D+Z (St04Z), DC52D+ZF | ≤0.08 | - | ≤0.45 | ≤0.030 | 0.03 | |

| DC53D+Z (St05Z), DC53D+ZF | ≤0.08 | - | ≤0.40 | ≤0.030 | 0.03 | |

| DC54D+Z (St06Z), DC54D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | 0.03 | |

| DC56D+Z (St07Z), DC56D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | 0.03 | |

| hot rolled steel sheet | DD51D+Z (St01ZR, St02ZR) | ≤0.10 | - | ≤0.50 | ≤0.035 | 0.03 |

| DD54D+Z (St06ZR) | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | 0.03 | |

Substrate Types

Hot-Dip Galvanized Color Coated Steel Sheet

(Prepainted Galvanized Steel Sheet)

This product is made by applying an organic coating over hot-dip galvanized steel. In addition to the corrosion protection provided by the zinc layer, the organic coating offers an additional barrier against rust. As a result, it has a longer service life compared to standard hot-dip galvanized sheets.Hot-Dip Aluzinc Color Coated Steel Sheet

(Prepainted Galvalume Steel Sheet)

Hot-dip Aluzinc substrates, typically composed of 55% aluminum and 45% zinc (or 5% AI-Zn variants), can also be used for color-coated applications. These sheets offer excellent corrosion resistance and thermal reflectivity.Electro-Galvanized Color Coated Steel Sheet

(Prepainted Electro-Galvanized Steel Sheet)

Produced by applying an organic coating to electro-galvanized steel, this type features a smooth surface finish, attractive appearance, and excellent formability. It is widely used in applications such as home appliances, audio equipment, steel furniture, and interior decoration.

Types of Colour Coating

Standard Polyester (PE)

Good gloss retention, color stability, and cost-effectiveness; suitable for general-purpose applications.Matt Polyester

Offers a soft, non-reflective surface with enhanced aesthetic appeal; ideal for architectural projects.Decoprint

A printed decorative coating that simulates textures such as wood grain or stone; commonly used for indoor decoration and high-end finishes.

Coating Types

Polyester (PE)

Offers good adhesion and a wide range of vibrant colors. Known for its excellent formability and decent outdoor durability. It provides medium chemical resistance at a relatively low cost, making it suitable for general-purpose applications.Silicon Modified Polyester (SMP)

Provides good abrasion and heat resistance. Features improved durability and resistance to chalking and fading in outdoor environments. Maintains moderate gloss retention and flexibility, with a medium price point.High Durability Polyester (HDP)

Delivers excellent color retention and UV resistance. Ideal for harsh outdoor conditions thanks to its strong resistance to chalking and weathering. Offers superior paint film adhesion, vibrant color options, and outstanding cost performance.Polyvinylidene Fluoride (PVDF)

Known for top-tier color retention and exceptional resistance to UV rays and weathering. Exhibits excellent solvent resistance, stain resistance, and chalking resistance. Offers good formability, though available in limited color ranges and at a higher cost.

The Production Process

Product Testing

PPGI

(Prepainted galvanized steel coil or sheet)Paint Coating Test

Measures the thickness and uniformity of the paint layer.Zinc Coating Test

Evaluates the zinc layer weight and consistency.Thickness Test

Verifies overall material thickness using a micrometer.Width Test

Ensures dimensional accuracy across coil or sheet width.Impact Test

Assesses the coating’s ability to resist impact without cracking or detaching.Bending Test

Checks the flexibility of the coated steel during bending without peeling or cracking.Gloss Measure

Evaluates surface gloss to meet visual or decorative standards.

Product Application

Automotive industry

Facade panels

Fence

Household appliances

Metal tiles

Non-standard design project

Sandwich panels

Siding

Water drainage system

Agricultural machinery

Guards

(1)In the construction industry: to manufacture exterior and Interior products such as metal shingles, corrugated sheeting, sandwich panels, profiles, metallic ceilings, skirting boards, decorative panels inside heated and non- heated rooms, elevators, doors window shutters, shelves etc.

(2)In the automotive industry: to manufacture external and internal car body parts (car doors, car boots, oil filters, dashboards, windscreen wipers etc.

(3)In manufacture of home appliances, furniture, and consumer goods: metallic furniture, lighting equipment, shelves, radiators, сar doors, car boots etc.

FAQ

1.Will you deliver the goods on time?

Yes,we promise to provide best quality products and delivery in time no matter if the price change lot or not, Honesty is our company's tenet.

2.How can I get your quotation as soon as possible?

The email and fax will be checked in 24 hours, meanwhile, the skype will be online in 24 hours Please tell us the order information about quantity, Specification(steel type, material, size )and destination port, you will get the latest price.

3.How about the sample if i need?

The sample will be offered for free if you need, but the freight will be covered by our customer. If we have cooperation, the freight will be covered by our company.

4.How about the MOQ?

Generally, the trail order will be accepted.The MOQ can be confirmed according to the different products. For example, the MOQ of PPGI will be 10MT.

5.How about the delivery time?

Within 15-30days after receiving the deposit or L/C at sight. Of course, the detail will be confirmed by the quantity and the different products.

6.How to order?

Please send us your purchase order by email. Or you can ask us to send you a proforma invoice for your order. We need to know the following information for your order.

7.What is shipment terms?

1. Container ship 2. bulk ship 3. Train

8.Do you have English Mill Test Certificates?

Yes,that is what we give gurantee to our clients9.Do you accept the third party inspection?Yes,absolutely we accept.