- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-15 Origin: Site

Have you ever wondered what makes expanded sheet metal mesh such a versatile material in construction and design? This lightweight yet strong material offers unique benefits, but its true potential is unlocked with plastic coating. In this post, you'll learn about the importance of plastic coating and its applications, enhancing durability and aesthetic appeal.

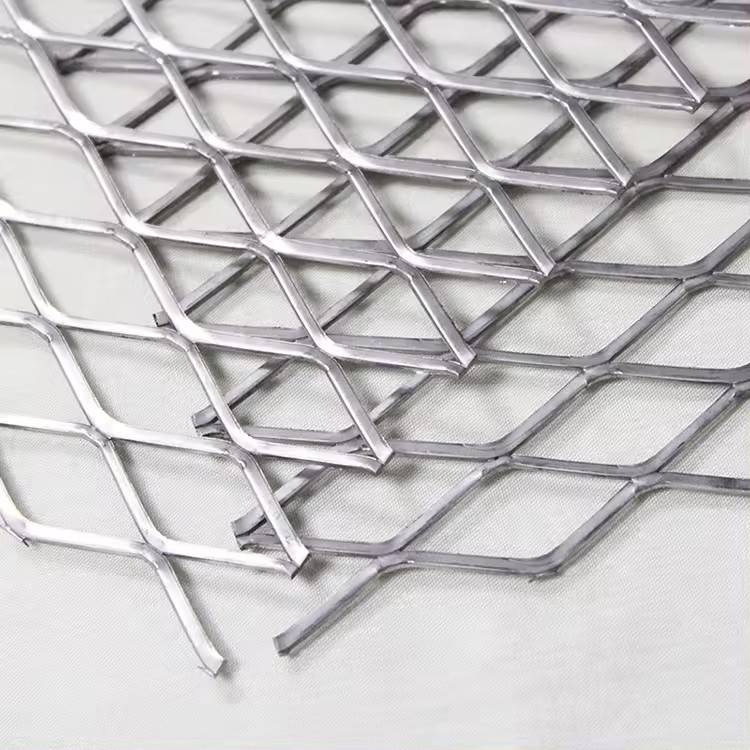

Expanded sheet metal mesh is a single sheet of metal that has been cut and stretched to form a mesh-like pattern. This process creates a network of diamond-shaped openings without welding or weaving. The metal sheet is literally expanded, which means it gains strength and rigidity while remaining lightweight. Common metals used include steel, aluminum, and stainless steel.

This mesh is not fabricated by joining wires but by expanding a solid sheet, resulting in a continuous piece with no weak points. Its open structure allows light, air, and fluids to pass through easily, making it ideal for applications requiring ventilation or filtration.

● Strength and Durability: Because the mesh is made from a single piece of metal, it offers excellent structural integrity. It resists deformation under stress better than many woven or welded meshes.

● Lightweight: Expanded metal mesh retains strength but reduces overall weight. This makes it easier to handle and install, and it reduces load on supporting structures.

● Versatility: The mesh can be manufactured in various thicknesses, strand widths, and opening sizes to suit different needs. It can be flat or formed into shapes such as cylinders or panels.

● Cost-Effective: The manufacturing process creates minimal waste, as the metal sheet is stretched rather than cut away. This efficiency can lower material costs.

● Safety: The mesh's edges are often smooth, reducing the risk of cuts during handling. Its open design also allows visibility and ventilation, useful for safety barriers or fencing.

● Corrosion Resistance: When made from corrosion-resistant metals or coated, the mesh withstands harsh environments, extending its lifespan.

● Aesthetic Appeal: Its geometric pattern offers a modern, industrial look. It is often used in architectural designs to add texture and visual interest.

Expanded sheet metal mesh serves many industries, from construction and architecture to manufacturing and security. Its combination of strength, lightness, and adaptability makes it a practical and attractive choice for a wide range of projects.

Plastic coating significantly boosts the durability of expanded metal mesh. The coating forms a protective layer that shields the metal from scratches, impacts, and wear. This extra barrier prevents the mesh from degrading quickly, even under heavy use or in demanding environments. The plastic layer acts like a cushion, absorbing minor shocks and reducing damage from abrasion. As a result, the mesh maintains its structural integrity longer than uncoated metal.

Moreover, plastic coatings help prevent metal fatigue caused by repeated stress. This means the mesh stays strong and reliable over extended periods, reducing the frequency of repairs or replacements. For industries like construction or manufacturing, this extended lifespan translates into cost savings and less downtime.

One of the most important benefits of plastic coating is its ability to protect expanded metal mesh from corrosion. Metal exposed to moisture, chemicals, or salty air can rust or corrode, weakening the mesh over time. The plastic coating acts as a waterproof barrier, preventing water and corrosive agents from reaching the metal surface.

This is crucial for outdoor applications where the mesh faces rain, humidity, or pollution. The plastic layer also blocks UV rays, which can degrade unprotected metal and cause discoloration or brittleness. By resisting these environmental factors, plastic coated expanded metal mesh remains functional and visually appealing for years.

Additionally, the coating resists exposure to chemicals, oils, and solvents, making it suitable for industrial environments. Whether used in factories, coastal areas, or landscaping, the plastic coating ensures the mesh withstands harsh conditions without losing performance.

● Protects metal from scratches, impacts, and wear

● Extends structural integrity and lifespan

● Prevents metal fatigue from repeated stress

● Acts as a waterproof barrier against moisture and corrosion

● Shields metal from UV damage and environmental pollutants

● Resists chemical exposure in industrial conditions

These advantages make plastic coated expanded metal mesh a reliable choice for projects requiring strength and long-term performance.

Plastic coated expanded metal mesh plays a vital role in construction and architecture. Its strength and lightweight nature make it ideal for building facades, sunshades, and decorative panels. The plastic coating protects the mesh from weather damage, ensuring it looks good and lasts long even when exposed to rain or sunlight.

Architects appreciate the mesh for its modern, industrial aesthetic. It adds texture and depth to buildings, creating visual interest without blocking light or airflow. The coating comes in various colors, allowing designers to match or contrast the mesh with other materials. This versatility helps in customizing buildings to meet both functional and creative demands.

In addition, the mesh offers practical benefits in construction. It can be used as reinforcement in concrete or plaster applications, improving structural integrity. The coated surface prevents corrosion, which is crucial for outdoor or humid environments. This means less maintenance and longer service life for building components.

Safety barriers and fencing often require materials that combine strength, visibility, and durability. Plastic coated expanded metal mesh fits these needs perfectly. The coating adds a protective layer that reduces the risk of injury from sharp edges, making it safer to handle and install.

The mesh's open design allows for clear visibility, which is important for security fences or crowd control barriers. It lets light and air pass through, preventing the creation of blind spots and reducing wind resistance. This makes fences more stable and less likely to suffer damage during storms.

In industrial settings, plastic coated mesh fences protect machinery and workers. The coating resists chemicals and moisture, ensuring the fence remains intact in harsh environments. For public spaces, the coated mesh provides a secure yet attractive solution for parks, sports facilities, or construction sites.

Its customizable colors help match safety barriers to corporate branding or local regulations. This flexibility supports both functional safety and aesthetic integration in various settings.

Before applying any plastic coating, the metal surface must be thoroughly prepared. Proper preparation ensures strong adhesion and a smooth, durable finish.

1. Cleaning: Remove all dirt, grease, oil, and other contaminants. This can be done using solvents, detergents, or alkaline cleaners. Any residue left on the metal will weaken the bond between the coating and the mesh.

2. Rust and Scale Removal: If the mesh has rust or mill scale, these must be eliminated. Mechanical methods like wire brushing, abrasive blasting, or sanding are common. Chemical treatments such as acid pickling can also be used, especially for steel.

3. Surface Profiling: Creating a slightly rough surface helps the coating grip better. Abrasive blasting not only cleans but also profiles the metal. The profile should be consistent to avoid uneven coating thickness.

4. Drying: After cleaning and profiling, the mesh needs to be completely dry. Moisture trapped under the coating can cause bubbling or peeling later.

5. Pre-Treatment: Sometimes a primer or conversion coating (like phosphate or chromate treatments) is applied. This step enhances corrosion resistance and improves coating adhesion.

Once the metal is ready, the plastic coating can be applied through several methods. Polyester powder coating is popular for expanded metal mesh due to its durability and finish quality.

1. Powder Application: The mesh is sprayed with an electrostatically charged powder. The charged particles stick evenly across the metal surface, including edges and inside the mesh openings.

2. Curing: After powder application, the mesh enters an oven. Heat melts the powder, causing it to flow and form a continuous, smooth skin. Curing time and temperature depend on the powder type but typically range from 15 to 30 minutes at 180-200°C (350-390°F).

3. Cooling: The coated mesh cools down to harden the plastic layer. This solid coating protects the metal beneath.

4. Inspection: After cooling, the mesh is inspected for coverage, thickness, and defects such as runs or pinholes. Any flaws can be repaired or recoated.

5. Additional Coats: For extra protection or specific finishes, multiple layers or clear coats may be applied.

Alternative coating methods include dip coating, where the mesh is submerged in a liquid plastic solution, or spray coating with liquid paints or plastisol. Each has pros and cons related to thickness control, finish texture, and environmental impact.

Polyester powder coating is one of the most popular plastic coatings used on expanded sheet metal mesh. It involves applying a dry powder electrostatically to the metal surface, which is then cured under heat to form a durable, smooth finish. This coating is tough, resistant to chipping, scratching, and fading, making it ideal for outdoor and industrial applications.

The advantages of polyester powder coating include:

● Durability: It creates a hard finish that withstands wear and tear better than traditional paint.

● Color Variety: Available in many colors and finishes, allowing customization.

● Environmental Safety: It emits no volatile organic compounds (VOCs), making it eco-friendly.

● Corrosion Resistance: When combined with proper surface preparation, it enhances protection against rust and corrosion.

Polyester powder coating adheres well to steel, aluminum, and stainless steel expanded mesh. It also provides consistent coverage on the mesh’s intricate shapes, including edges and openings. This ensures uniform protection and aesthetic appeal.

Anodising is a unique coating method mostly applied to aluminum expanded metal mesh. Unlike powder coating that sits on the surface, anodising thickens the natural oxide layer of the metal itself. This process improves corrosion resistance, hardness, and wear resistance while preserving the metal’s metallic sheen.

Key features of anodising include:

● Longevity: The finish remains vibrant and intact for decades, even in harsh environments.

● Color Options: Anodising allows subtle color variations, from natural metallic shades to tinted finishes.

● Maintenance: The anodised surface is easy to clean and maintain.

● Eco-Friendly: It uses fewer chemicals than other coating processes and produces minimal waste.

Other specialist coatings for expanded metal mesh include:

● PVC Coating: Offers thick, flexible protection ideal for heavy-duty applications.

● Fluoropolymer Coatings: Provide superior UV resistance and chemical resistance.

● Epoxy Coatings: Used mainly for industrial environments requiring strong chemical protection.

Each coating type serves different needs depending on the mesh's application, environment, and aesthetic requirements. For example, an architectural project might benefit from polyester powder coating's color range, while a marine environment could call for anodising or fluoropolymer coatings for enhanced corrosion resistance.

Tip: When selecting a plastic coating, consider the mesh's material, environment, and desired finish to ensure optimal performance and longevity.

Plastic coating opens a wide range of color and finish choices for expanded sheet metal mesh. Manufacturers offer coatings in numerous hues, from bold reds and blues to subtle earth tones and metallic shades. This variety allows designers and architects to match the mesh to a building's color scheme or brand identity.

Finishes can also vary beyond just color. Options include matte, gloss, satin, or textured surfaces. Each finish affects the mesh’s appearance and feel differently. For example, a matte finish reduces glare, making it ideal for outdoor facades in bright sunlight. Glossy finishes, on the other hand, provide a sleek, modern look often favored in interior applications.

The plastic coating can also be translucent or opaque, giving additional control over how much light passes through. This flexibility is especially useful in architectural projects where light diffusion or privacy is desired.

Beyond color and finish, plastic coated expanded metal mesh offers tremendous design freedom. The coating process covers every part of the mesh, including edges and inside openings, ensuring consistent protection and color throughout. This uniformity lets designers use the mesh in complex shapes or curved surfaces without worrying about exposed metal or uneven appearance.

Creative applications include combining different colors or finishes on the same mesh panel to create patterns or gradients. Some manufacturers even offer custom printing or embossing on coated mesh, adding logos or decorative elements directly onto the surface.

Plastic coatings also allow for layering effects. For example, a base color can be coated with a clear textured layer to simulate natural materials like stone or wood grain. This enhances the mesh’s visual interest while maintaining its durability.

Because the mesh is lightweight and strong, it can be integrated into innovative architectural features such as sunshades, partitions, or ceiling panels. The coating ensures these elements withstand weathering and wear while maintaining their aesthetic appeal.

Expanded sheet metal mesh is highly recyclable, making it an eco-friendly choice for many projects. Since the mesh is made from metals like steel, aluminum, or stainless steel, it can be melted down and reused without losing its properties. This recyclability helps reduce waste and lowers the demand for new raw materials, which conserves natural resources.

When plastic coating is applied, it’s important to consider how it affects recycling. Some coatings can be removed during the metal recycling process through heat or chemical treatments, allowing the underlying metal to be recovered efficiently. Choosing coatings that are compatible with recycling processes helps maintain the mesh’s sustainability benefits.

Recycling metal mesh also reduces energy consumption compared to producing metal from ore. For example, recycling aluminum saves up to 95% of the energy required for primary production. This energy saving translates into lower greenhouse gas emissions and a smaller carbon footprint for projects using recycled metal mesh.

Plastic coatings vary widely, but many manufacturers now offer eco-friendly options that support sustainability goals. These coatings often use materials with lower environmental impacts, such as powders free from volatile organic compounds (VOCs) or bio-based plastics derived from renewable sources.

Powder coatings are particularly eco-friendly because they emit no VOCs during application. They also produce minimal overspray waste, which can be collected and reused. This reduces air pollution and material waste compared to traditional liquid paints.

Some companies develop plastic coatings that are easier to recycle or degrade more safely at the end of their life cycle. Others focus on coatings that extend the mesh's lifespan, reducing the need for replacement and lowering overall resource consumption.

Selecting eco-friendly plastic coatings aligns with green building standards and certifications such as LEED or BREEAM. Using these coatings on expanded metal mesh helps projects meet sustainability targets while delivering durable, attractive results.

Applying plastic coating to expanded sheet metal mesh enhances its durability and corrosion resistance, providing long-lasting protection. The process involves thorough surface preparation and careful coating application for optimal results. As the demand for eco-friendly and sustainable building materials grows, plastic-coated expanded metal mesh is expected to gain popularity across various industries. Companies like Shengteng International Trading offer high-quality products that combine strength, aesthetics, and sustainability, delivering exceptional value for construction and architectural projects.

A: Expanded sheet metal mesh is a single sheet of metal cut and stretched to form a mesh-like pattern with diamond-shaped openings, providing strength, rigidity, and lightweight properties.

A: To apply plastic coating, clean the mesh, remove rust, create a rough surface, dry it, and apply powder coating, then cure it in an oven for a durable finish.

A: Plastic coating enhances durability, corrosion resistance, and UV protection, extending the lifespan and performance of expanded sheet metal mesh.

A: Benefits include protection from scratches, corrosion resistance, UV shielding, and extended structural integrity, making it suitable for various environments.